The selection of starting systems for marine diesel engines is crucial for the normal operation of equipment at sea. Air starting system in marine diesel engine is a widely used and effective method.

However, is air starter the only option for starting marine diesel engines? Certainly not. For example, spring starter, a power-free starting device, has increasingly been applied in marine starting, particularly in special situations. We will delve into these two starting systems here.

Part 1. What is Air Starting System in Marine Diesel Engine?

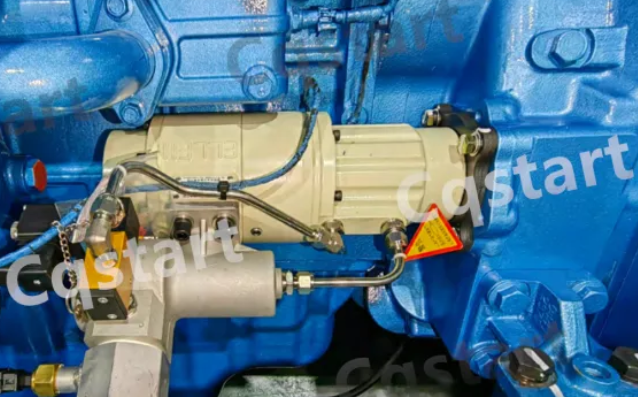

Air starter is a device that uses compressed air to start marine diesel engines. It does not rely on electricity and has high reliability, allowing the engine to be started even in situations where power is insufficient or during emergencies. It is primarily used for starting the main and auxiliary engines on ships, making it especially suitable for high-power diesel engines.

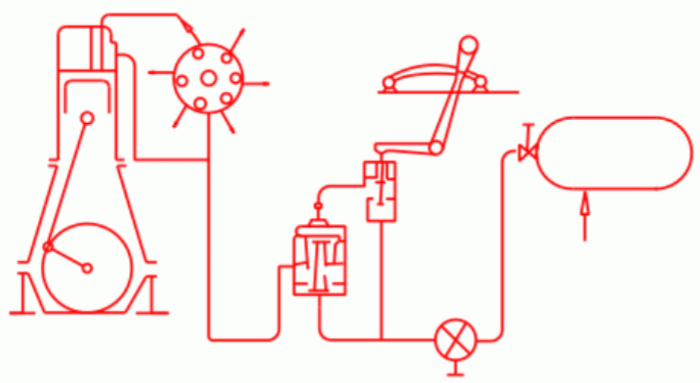

Components of Air Starter

What does an air starter consist of? Below are the components of an air starter:

Air Compressor: It’s responsible for compressing air to the required pressure (usually 20-30 bar) and delivering it to the storage tank. The air compressor can be driven by an electric motor or an engine.

Storage Tank: It’s used to store high-pressure air to ensure there is enough compressed air supply during the start-up process. The capacity of the storage tank is typically large to meet the demands of multiple starts or extended use.

Starting Air Control Valve: During startup, this valve distributes high-pressure air to each cylinder. The operation of the control valve is usually managed by a start button or an automatic control system, ensuring that high-pressure air enters the cylinders in the correct sequence.

Air Distributor: It is responsible for distributing compressed air to each cylinder in order to start the engine smoothly. Precise control of the distributor is key to ensuring a successful start.

Piping System: The network of pipes that connects the compressor, storage tank, control valves, and engine cylinders, used for transporting compressed air.

Part 2. How Does Air Starter Work?

The basic principle of an air starter is to utilize the high-pressure energy of compressed air to drive the pistons of the diesel engine, rotating the engine and starting the engine. The specific steps are as follows:

Compressed Air Supply: The air starting system relies on an air compressor to generate high-pressure air, which is typically stored in one or more storage tanks. The air in the system is usually compressed to a high pressure of 20-30 bar to ensure sufficient energy is converted into diesel engine power.

Air Distribution: When the command to start the engine is given, the control valve opens, directing the high-pressure air from the storage tank into the cylinders. At this stage, compressed air enters the diesel engine’s cylinders through the starting valve, pushing the pistons downward and simulating the compression stroke that occurs during normal engine operation.

Engine Rotation: Compressed air is injected into multiple cylinders, causing the pistons and crankshaft to begin rotating. The engine gradually reaches the ignition speed. When the engine reaches the required speed for self-ignition, the fuel system starts injecting fuel, and the engine enters its normal combustion state, successfully starting.

Part 3. Pros & Cons of Air Starting in Marine Diesel Engine

Pros of Air Starting

- Efficiently Starting High-Power Diesel Engines: Air starter is particularly suitable for starting large, high-compression diesel engines that require a substantial initial torque during startup.

- High Reliability: Air starter does not rely on electricity, allowing it to start the engine even when power supply is unstable or in the event of battery failure.

- Adaptability to Marine Environments: Air starter is not easily affected by moisture, salt spray, and other environmental factors, making it especially suitable for vessels operating at sea for extended periods.

Cons of Air Starting

- Large Volume and Space Occupation: The air compressor, storage tank, and piping system take up significant space on the vessel, making installation and maintenance more complex for smaller ships or compact machinery.

- Dependence on Compressed Air: Insufficient compressed air in the storage tank may lead to startup failures. Therefore, it is essential to pay special attention to maintaining adequate compressed air reserves during routine maintenance.

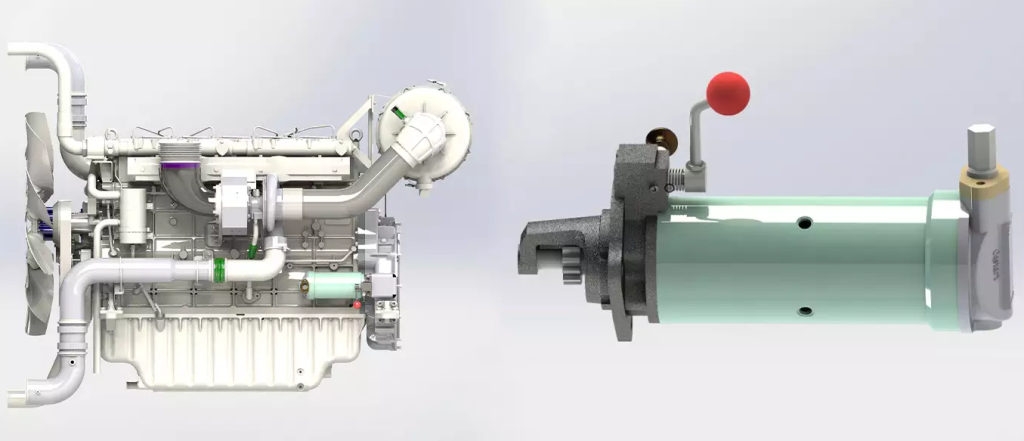

Part 4. Spring Starter – Best Alternative to Air Starter in Marine Application

Compared to air starter, spring starter is a mechanical starting device that does not require external power sources or compressed air. Its working principle involves manually or mechanically winding a high-power spring to store mechanical energy. When an engine needs to start, the energy from the spring’s release drives the crankshaft, starting the engine.

Advantages of Spring Starter

No External Power Required: Spring starter does not rely on batteries or compressed air at all, making it particularly suitable for environments with limited power supply or confined spaces.

Simple Structure and Low Maintenance Costs: The mechanical structure of spring starter is simple and requires almost no maintenance, making it suitable for long-term use.

Strong Applicability: It is especially well-suited for diesel engines such as emergency generators and auxiliary equipment on vessels.

Part 5. Comparison of Air Starter & Spring Starter

| Features | Air Starter | Spring Starter |

| Working Principle | Uses compressed air to drive engine startup | Tightly winds a spring manually or mechanically to release energy for engine startup |

| Power Source Dependency | Requires an air compressor and storage tank, typically relying on external power | Completely independent of electricity or compressed air |

| Maintenance | Requires regular inspection and maintenance of the compressor and piping system | Low maintenance costs, requiring almost no special care |

| Space Requirements | Occupies a large space, suitable for large vessels or equipment | Occupies less space, suitable for compact equipment |

| Applications | Marine diesel engines, offshore platforms, and other scenarios requiring high starting torque. | Ship emergency generators, marine auxiliary equipment, and devices with limited space that do not require frequent starts. |

Final Thoughts

Although air starter plays an important role in starting marine engines and is widely used due to its efficiency and reliability, it is not the only option. In many cases, especially in environments with limited power supply or restricted space, spring starter demonstrates unique advantages and is gradually becoming an indispensable part of the starting system for marine diesel engines.