Big diesel engines, often referred to as the “heart” of various industries, play a crucial role in transportation, agriculture, and manufacturing. However, as these engines age, they may encounter starting issues due to battery aging, mechanical wear, or other factors.

So, how can we solve these frustrating “engine dormancy” problems? In this article, we will dive deep into the common causes of these issues and provide practical and efficient solutions to easily tackle the challenges of big old diesel engines starting.

Part 1. Challenges in Starting Big Old Diesel Engines

Common Causes of Big Old Diesel Engine Starting Issues

There are various reasons why old diesel engines struggle to start, and understanding these issues is crucial for maintaining optimal engine performance. Let’s delve deeper into the main causes.

1. Weak or Dead Battery

The battery is the lifeblood of a diesel engine’s starting system. It provides the initial electrical power required to turn over the engine and initiate the combustion process.

In cold weather, the battery’s capacity can significantly diminish due to the lower temperatures, which reduce its ability to generate power. This is particularly true for older batteries or those that have been in use for several years.

When a battery weakens or loses charge, it may not provide enough cranking power to start the engine, even though the engine may appear to turn over slowly or not at all.

2. Fuel Problems

Fuel issues are another common cause of starting difficulties in old diesel engines. Over time, diesel fuel can degrade, particularly when left in the tank for long periods without use. This degradation leads to the formation of sediment, sludge, and gums that can clog fuel lines, filters, and injectors.

3. Mechanical Wear

With age and prolonged use, the mechanical components of a diesel engine inevitably experience wear and tear. This is especially true for older engines that have been running for thousands of hours.

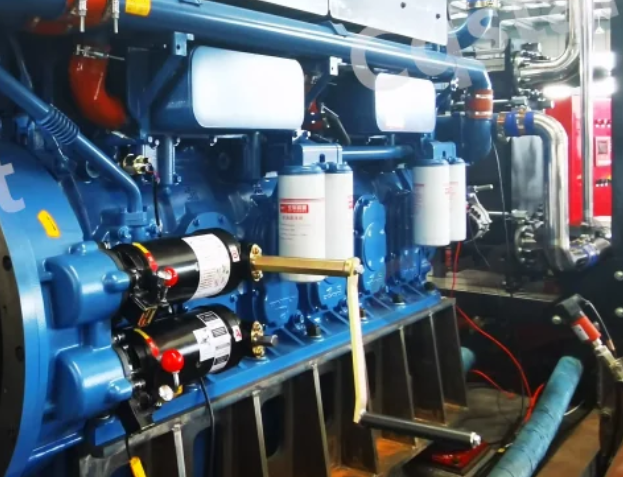

Components such as the starter motor, glow plugs, injectors, fuel pumps, and the engine’s internal parts can degrade over time, which increases resistance when starting the engine.

4. Cold Weather Impact

Cold weather is one of the most significant external factors affecting the starting performance of diesel engines. Diesel fuel tends to thicken and gel at low temperatures, which can cause fuel to become less fluid and more prone to clogging. This is particularly problematic in cold climates where temperatures drop below freezing.

Common Starting Symptoms

When an old diesel engine struggles to start, there are several common symptoms that can help diagnose the underlying issue. Let’s explore these symptoms in greater detail:

1. Engine Turns But Doesn’t Start

One of the most common symptoms of a starting problem is when the engine cranks (turns over), but fails to start. In this case, the starter motor is functioning to rotate the engine, but the combustion process does not begin, and the engine does not fire up. This symptom is usually caused by issues related to the fuel system or the battery.

2. Engine Won’t Crank

In this case, when you turn the key or press the start button, the engine doesn’t turn over at all, or it cranks very slowly, or cranks but not starting. This indicates that the starter motor is not engaging properly, and the engine is unable to begin its rotation. This is often caused by issues with the battery or the starting system.

3. White or Black Smoke

When attempting to start the engine, if you notice white or black smoke coming from the exhaust, it’s an indication that something is wrong with the combustion process. Diesel engines typically produce some exhaust smoke when starting, but excessive or unusual smoke is a sign that further investigation is needed.

Part 2. How to Effectively Start Big Old Diesel Engines?

Starting big old diesel engines can be challenging. However, by following the right procedures and maintaining key components, you can significantly improve the chances of a smooth startup. Here’s how to effectively start big old diesel engines:

1. Check the Battery Condition

The battery is a crucial component of the starting system in any diesel engine, but it is especially vital in older engines. Diesel engines require a strong electrical charge to power the starter motor, fuel injectors, and glow plugs, particularly in cold weather. The battery is most susceptible to degradation over time, and extreme temperatures can exacerbate the issue.

Key Steps:

- Test the Voltage: Regularly check the battery’s voltage using a multimeter. A healthy, fully charged battery should read around 12.6 volts. If the voltage is significantly lower, it’s time to recharge or replace the battery.

- Clean the Terminals: Corroded battery terminals can cause poor connections, reducing the flow of current to the starter motor. Clean the battery terminals using a mixture of baking soda and water or a specialized terminal cleaner to remove corrosion.

- Ensure Tight Connections: Loose or improperly connected battery cables can result in intermittent starting issues. Tighten the battery connections and ensure there is no corrosion around the terminals.

- Jump-Start the Engine: If the battery is weak but still functional, you can use an external power source, such as jumper cables or a jump starter, to temporarily provide the necessary power. This is especially useful when the engine cranks but fails to start due to low voltage.

2. Inspect the Fuel System

The fuel system plays a crucial role in ensuring proper combustion and efficient engine startup. Over time, diesel fuel can degrade, leading to the formation of sediment, sludge, and water contamination, which can clog the fuel lines, filter, and injectors. If the engine has been sitting idle for an extended period, the fuel may have become problematic, making it difficult to start.

Key Steps:

- Check the Fuel Quality: Examine the fuel in the tank. Big old diesel fuel can develop a foul smell or appear cloudy if it has absorbed water. In such cases, drain the old fuel and replace it with fresh, clean fuel to ensure proper engine function.

- Replace the Fuel Filter: Fuel filters trap debris, dirt, and contaminants from the fuel before they reach the engine. Over time, these filters can become clogged, restricting the flow of fuel. Regularly replacing the fuel filter, especially after long periods of inactivity, helps prevent fuel delivery problems.

- Inspect the Fuel Lines: Check the fuel lines for signs of cracks, leaks, or damage. Even small leaks can introduce air into the fuel system, leading to starting difficulties. Replace any damaged or cracked fuel lines.

- Clear Fuel Blockages: If the engine has trouble starting or is producing smoke, it could be a sign of a blockage in the fuel system. Consider using a fuel system cleaner or contacting a professional to clear any obstructions in the injectors, fuel lines, or tank.

3. Use Auxiliary Starting Equipment

For big old diesel engines that have difficulty starting, especially in cold conditions or when the battery is weak, using external auxiliary starting equipment can make a significant difference.

For instance, spring starter, such as Cqstart 0 Group System Spring Starter for big diesel engine, can provide additional mechanical energy to assist with starting, reducing the strain on the battery and the starter motor.

What is a Spring Starter?

Spring starter is a mechanical device that uses a wound spring to store energy. When engaged, the spring releases its stored energy, providing a burst of power to turn the engine over. This additional power helps get the engine running when the regular starting system struggles, such as during extremely cold weather or when the battery is low on charge.

Key Benefits of Spring Starter for Big Old Diesel Engine:

- No Need for Batteries or Air Source: Spring starters do not rely on batteries or air pressure sources, reducing maintenance costs and eliminating the hassle of battery replacements.

- High Reliability: Even in cold or extreme environments, spring starters operate reliably because their mechanism is based on mechanical force, eliminating the impact of temperature on battery performance.

- Easy Operation: The spring starter features a simple design that is easy to maintain, typically requiring only regular checks of the spring and starting mechanism.

- Emergency Backup Solution: In the absence of electricity, the spring starter serves as an emergency backup to start the engine, ensuring the equipment starts smoothly when it matters most.

How to Use Spring Starter:

- Ensure the spring starter is properly installed according to the manufacturer’s instructions.

- Wind the spring and engage the mechanism when attempting to start the engine. The stored energy from the spring will provide a significant boost to the engine’s cranking power.

- Regularly maintain the spring starter by lubricating the moving parts and checking for wear.

Part 3. How to Maintain Big Old Diesel Engines?

1. Regularly Check the Battery and Starting System

Ensure the battery is fully charged, and the battery terminals are clean and tightly connected. A weak or old battery is one of the most common reasons for starting issues, especially in cold weather.

If the battery is showing signs of wear or is over 3-5 years old, consider replacing it to avoid unexpected starting problems. Additionally, check the condition of the starter motor and the wiring connections to ensure everything is functioning properly.

2. Clean the Fuel System and Air Filter

Over time, dirt and debris can accumulate in the fuel system, affecting fuel delivery. Regularly replace the fuel filter to prevent blockages and ensure the engine is receiving clean fuel.

Also, check the fuel lines for leaks or cracks, as these can introduce air into the system and cause starting problems. The air filter should be cleaned or replaced regularly to ensure proper airflow to the engine, as a clogged air filter can reduce engine performance and make it harder to start.

3. Use High-Quality Fuel and Lubricants

Using high-quality diesel fuel and engine oil significantly improves engine performance and longevity. Poor-quality fuel can lead to injector clogging, sediment build-up, and water contamination, all of which can cause starting issues.

Similarly, using the right grade of engine oil reduces friction and wear, making it easier for the engine to turn over, especially in cold weather. Always check for the appropriate additives for fuel and oil to maintain optimal engine health.

4. Regularly Inspect Engine Components

Periodically inspect key engine components such as the fuel injectors, glow plugs, and starter motor. Worn or damaged parts should be replaced promptly to prevent further damage and starting issues.

For instance, faulty glow plugs can make starting in cold weather difficult, while worn injectors can affect fuel atomization, leading to rough starting. Keep an eye on hoses, seals, and gaskets to ensure no leaks or cracks that could lead to air or fuel system issues.

In Summary

Starting large diesel engines, especially older ones, is indeed a challenge, but there are multiple methods to address this issue. If you’re looking for a reliable starting solution for your aging diesel engine, Cqstart spring starter is undoubtedly an option worth considering. It not only operates reliably without the need for external power but also helps reduce maintenance costs, ensuring that your equipment remains in good condition for the long term.iesel engine startup problems.