With the rapid development of global industrialization, many high-risk industries are raising higher safety requirements for diesel engines. In environments with flammable and explosive risks, ordinary diesel engines can pose significant dangers.

As a result, explosion-proof diesel engines have emerged. These engines not only provide powerful output but also maintain stable operation in high-risk environments, effectively preventing catastrophic accidents.

In this post, we will delve into everything about explosion proof diesel engines. More importantly, let you know how to make them more secure.

Part 1. What is Explosion Proof Diesel Engine?

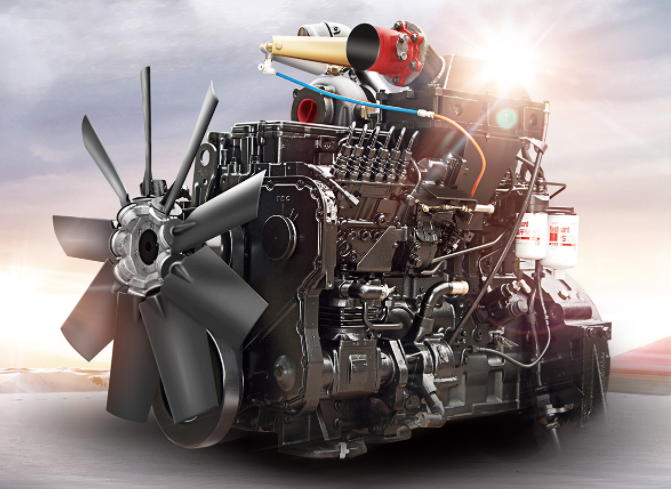

Explosion proof diesel engine is specifically designed for environments with flammable and explosive risks. Its main feature is its ability to operate safely in environments with potential explosion hazards.

The engine’s structural design and material selection are meticulously engineered to prevent sparks, heat, or static electricity from occurring during operation, thereby preventing the ignition of surrounding combustible gases or materials.

To meet international safety standards, explosion-proof diesel engines are typically required to obtain certifications such as ATEX (Atmosphere Explosible Directive) and IECEx (International Explosion Protection Certification). These certifications indicate that the engine can operate safely in explosive gas environments, meeting global industrial safety standards.

Part 2. Working Principle of Explosion Proof Diesel Engine

The basic working principle of an explosion-proof diesel engine is similar to that of a regular diesel engine, where mechanical energy is generated through the combustion of diesel.

However, unlike regular engines, explosion-proof diesel engines are specifically designed to handle the risks posed by flammable and explosive gases, and incorporate specialized protective measures. The key components of its working principle include:

Specialized Ignition System

The ignition system of an explosion-proof diesel engine is specially designed to prevent sparks or high temperatures from the electrical system, thus reducing the risk of fires or explosions.

Flameproof Enclosure Design

To withstand extreme working conditions, diesel engines equipped with a robust flameproof enclosure are commonly equipped with a flameproof enclosure. This enclosure effectively protects against internal explosions, preventing flames from spreading to the external environment.

Sealing Technology

Electrical components, fuel systems, and exhaust systems are meticulously sealed to prevent flammable gases from entering the engine, further reducing the likelihood of an explosion.

High-Temperature Resistant Materials

Engine internal components are typically made from high-temperature resistant and corrosion-resistant materials, such as stainless steel or aluminum alloys, to withstand extreme operating conditions and ensure the engine runs reliably over long periods.

Part 3. Applications of Explosion Proof Diesel Engine

Explosion-proof diesel engines are widely used in high-risk industries, particularly those involving flammable and explosive substances. These engines are crucial in the following application scenarios:

1. Oil and Gas Extraction

Oil and gas extraction often takes place in high-risk environments, especially on drilling platforms and in oilfield operations, where large quantities of flammable gases and vapors are present. In such hazardous environments, explosion-proof diesel engines play a critical role in providing efficient and stable power for drilling equipment.

These engines ensure safe operations without the risk of fire or explosion, even in the presence of volatile gases such as methane or hydrogen sulfide. Furthermore, the high durability and reliability of these engines help to prevent downtime in remote and challenging environments.

2. Chemical Industry

In the production of chemicals such as fertilizers, pharmaceuticals, paints, and other volatile substances, production lines often come into contact with flammable and explosive chemicals. Explosion-proof diesel engines are used to power machinery and equipment in these environments where any spark or high heat could lead to catastrophic explosions.

These engines are specially designed to prevent ignition sources from causing fires, ensuring that the power systems remain unaffected by external fire risks or high temperatures. This makes them ideal for maintaining the safety and efficiency of chemical plants, where volatile chemicals are handled regularly.

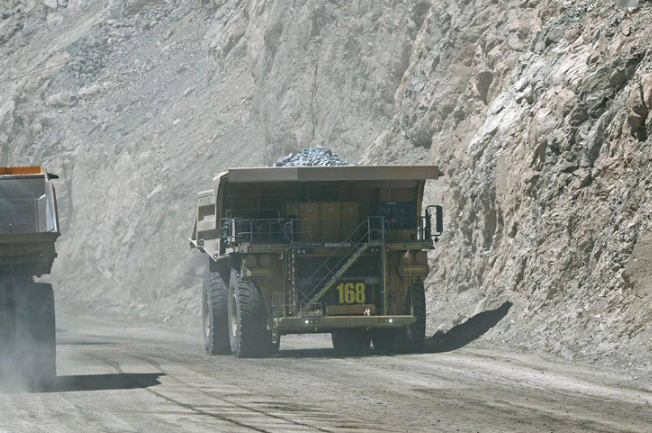

3. Mining Operations

Mines are environments where combustible gases like methane are often present, and using regular diesel engines could lead to disastrous explosions. Explosion-proof diesel engines offer a safer and more efficient alternative. These engines are used in mining operations to power equipment such as ventilation systems, drilling rigs, and haulage vehicles.

Since mines are typically located in remote areas, ensuring the safety and reliability of mining machinery is crucial. Explosion-proof diesel engines reduce the risk of ignition in areas where methane gas or other explosive substances are present, allowing mining operations to continue safely.

4. Hazardous Materials Storage

In the storage and transportation of flammable and explosive materials, explosion-proof diesel engines are widely used in equipment such as cranes, conveyor belts, and forklifts in warehouses.

These engines help prevent the risk of fire or explosion due to equipment malfunctions. In environments where hazardous chemicals, fuels, or explosives are stored or moved, any spark or heat could lead to a deadly disaster.

The use of explosion-proof engines in handling these materials ensures that the machinery operates without igniting sources, providing a secure working environment. These engines also help ensure smooth operations in logistics and supply chain processes where flammable substances are frequently involved.

5. Marine Applications

In marine environments, especially in offshore drilling and shipping, explosion-proof diesel engines are crucial for providing power to vessels and platforms in volatile environments. Marine environments are susceptible to unpredictable weather conditions, and when combined with the presence of flammable gases or fuels, the risk of explosion increases.

Explosion-proof diesel engines in marine applications are specifically designed to withstand harsh weather conditions while ensuring safe operations.

These engines are also used in emergency backup systems to ensure that essential equipment, such as pumps, generators, and compressors, remain operational without the risk of sparking fires in confined spaces.

6. Power Generation in High-Risk Areas

Explosion-proof diesel engines are increasingly being used in power plants in hazardous areas, including areas with high concentrations of combustible gases or facilities where explosive chemicals are produced.

These engines provide backup or primary power to ensure smooth operations, even in the event of a power failure. Their explosion-proof design ensures that even in the presence of hazardous gases or materials, the engine will not be a source of ignition.

They are vital in ensuring safe operation of critical systems in industries such as pharmaceuticals, petrochemicals, and even food production, where a continuous power supply is crucial in preventing accidents.

Part 4. How to Make Explosion Proof Diesel Engine More Secure?

In high-risk environments, the startup of diesel engines is critical, especially in areas filled with flammable, explosive gases or hazardous materials.

While explosion-proof diesel engines are designed for dependability and smooth operation in harsh conditions, spring starters have become a more dependable starting solution and improve the performance of explosion-proof diesel engines.

What is Spring Starter for Explosion Proof Diesel Engine?

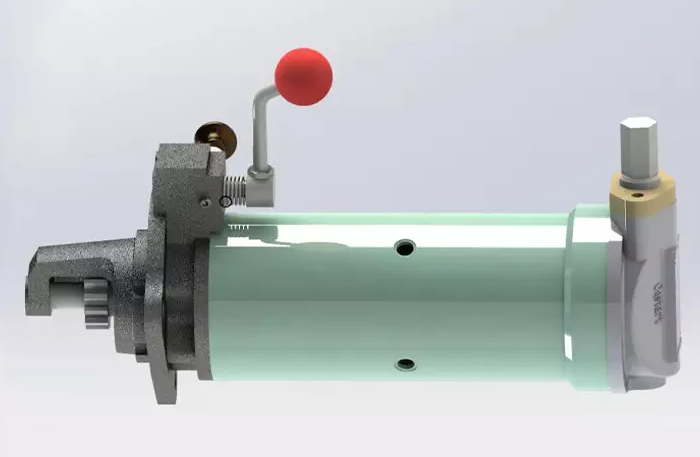

Spring starter, a mechanical starting device, works by storing energy in a pre-tensioned spring, which when needed, releases energy to start the diesel engine.

Compared to traditional electric starters, spring starters don’t rely on electrical systems, which is particularly crucial in high-risk environments. Electrical systems may cause sparks or high temperatures due to fluctuations or other failures, potentially leading to explosions.

Therefore, using a spring starter not only eliminates the potential risks associated with electrical systems but also ensures that the diesel engine starts quickly and reliably in extreme conditions, safeguarding the normal operation and safety of the equipment.

Best Spring Starter for Explosion Proof Diesel Engine

Cqstart spring starter is undoubtedly the best spring starter for explosion-proof diesel engines, as it combines advanced design concepts, exceptional performance, and unparalleled safety.

As a starting device specifically designed for high-risk environments, Cqstart spring starter provides a reliable and quick starting solution in flammable and explosive settings, making it the ideal choice for explosion-proof diesel engines.

Key Features of Cqstart Spring Starter

1. Outstanding Safety Performance

Cqstart spring starter has an anti-explosion feature for hazardous environments. Also, it relies entirely on mechanical drive, and does not use any electrical components, significantly reducing the risk of fire and explosion in flammable and explosive environments.

2. Efficient and Reliable Starting

Cqstart spring starter provides powerful starting energy through a high-quality spring system, enabling stable operation in low temperatures, humidity, or dusty environments.

3. High Adaptability

Cqstart spring starter features an environmentally protective special spray coating, making it highly suitable for harsh industrial environments, including extreme temperatures, high humidity, and dusty conditions.

Its robust mechanical design ensures exceptional performance even in demanding conditions, while significantly reducing maintenance requirements and lowering long-term operational costs.

4. Long-Term Stability and Durability

Cqstart spring starter is made from durable materials and advanced manufacturing processes, ensuring long-term stability. Its high wear resistance and corrosion resistance allow it to maintain high performance in harsh working environments, reducing maintenance and replacement parts.

Bottom Line

Explosion-proof diesel engines are crucial in modern industries, particularly in high-risk sectors such as oil, gas, and chemical industries. They provide a solid guarantee for the safety of work environments and production efficiency.

With the addition of a spring starter, it not only enhances the reliability of diesel engine starts but also reduces the risks caused by electrical failures, improving the engine’s adaptability and stability in harsh environments. This provides businesses with a more efficient and secure power solution.