On a cold winter night, a fully loaded heavy duty truck sits idle in the wilderness. The driver turns the key—without a powerful starter, this massive machine might not budge. And this is exactly when the heavy duty starter proves its worth!

Whether it’s a truck, excavator, agricultural machinery, or marine diesel engine, the heavy duty starter’s mission is to inject robust power into large and complex diesel engines, ensuring they fire up instantly, even in the harshest conditions.

Part 1. What is a Heavy Duty Starter?

A heavy duty starter is a specialized starting device designed for high-power diesel engines, widely used in heavy duty equipment such as trucks, construction machinery, ships, and generators. Since these engines require high torque to start, standard starters are often insufficient, making a more durable and powerful starting solution necessary.

Different operating conditions require different types of heavy duty starters. Common starting methods include:

- Electric Starter: Powered by a battery, commonly used in vehicles and equipment.

- Spring Starter: No battery or air required, uses spring energy storage to start, particularly ideal for remote or harsh environments with diesel engines.

- Pneumatic Starter: Relies on compressed air, suitable for ships and industrial applications.

So, which heavy duty starter is the best for your equipment? Let’s dive into the different types of starters and their pros and cons.

Part 2. Pros & Cons of Different Heavy Duty Starter Types

1. Electric Heavy Duty Starter

Pros:

- Mature design: Well-established technology with widespread application across various industries.

- Fast startup: Quick and efficient in initiating engine startup.

- Ease of operation: Simple to use and widely familiar to operators.

Cons:

- Battery dependence: Relies on the battery for power; insufficient battery charge can lead to startup failure.

- Regular maintenance: Requires periodic maintenance, including battery checks and replacements.

- Performance issues in extreme conditions: In harsh environments, such as freezing temperatures or high humidity, electric starters may experience decreased performance.

2. Spring Heavy Duty Starter — Eco-friendly and Efficient Starting Solution

Pros:

- No battery or air required: Uses mechanical spring energy storage to start the engine, making it highly reliable in remote areas where power sources may be unavailable.

- Ideal for extreme environments: Performs exceptionally well in conditions like extreme cold, high humidity, or when used in remote operations where electricity is not an option.

- Maintenance-free: There are no concerns about battery aging or the need for frequent checks. The system is almost entirely maintenance-free, ensuring long-term performance.

- Safe and reliable: With no risk of circuit damage or short circuits, it’s especially suitable for equipment that is stored for long periods, such as emergency generators.

- Long lifespan: Spring starters have an extended service life, as they are less prone to wear and tear compared to electrical systems.

Cons:

- Limited application range: May not be suitable for all types of heavy duty engines.

3. Pneumatic Heavy Duty Starter

Pros:

- Ideal for ships and industrial equipment: Perfect for environments where continuous engine starting is necessary.

- High reliability: Known for robust performance, even in harsh or remote environments.

- Efficient in challenging conditions: Works well in extreme temperatures or environments with limited electrical infrastructure.

Cons:

- Additional system requirements: Needs an external compressed air system, which increases installation costs and complexity.

- Complex maintenance: Requires regular maintenance of both the starter and the air supply system, and air quality plays a significant role in performance.

- Operational limitations: If the air supply is inadequate, it may cause failure in starting the engine.

Comparison Summary:

| Starter Type | Suitable Environments | Main Advantages | Main Disadvantages |

| Electric Starter | Vehicles, trucks, machinery | High popularity, easy to use | Requires battery, affected by environment |

| Pneumatic Starter | Ships, industrial equipment | High reliability, suitable for frequent starts | Requires air supply, high installation cost |

| Spring Starter | Remote areas, emergency equipment | No battery, maintenance-free, suitable for extreme environments | Limited engine power range |

➡ If your equipment requires high reliability, low maintenance costs, and the ability to operate in remote environments, the Spring Starter is the ideal choice!

Part 3. Applications of Heavy Duty Starter

Heavy duty starters are essential in a wide range of industries and equipment that require high-torque starting solutions. Here’s a detailed look at the key applications:

1. Trucks (Long-Distance Hauling, Heavy duty Trucks, and Trailers)

Heavy duty starters are crucial for trucks, including long-haul freight trucks, heavy duty semi-trucks, and tractors. These vehicles rely on high-torque starters to power large diesel engines, especially in harsh conditions like cold weather or heavy loads.

A reliable starter ensures that these trucks can get moving without delays, minimizing downtime and enhancing operational efficiency for fleet owners and operators.

2. Construction Equipment

Heavy duty starters are commonly used in construction machinery such as excavators, bulldozers, loaders, and cranes. These machines often work in challenging environments like construction sites with dust, mud, or extreme temperatures.

A heavy duty starter ensures that these engines start reliably, even under heavy load conditions, so construction projects can proceed smoothly without unnecessary delays.

3. Agricultural Machinery

For farming equipment like tractors, combine harvesters, and other agricultural machinery, heavy duty starters are essential to keep operations going without interruption.

These machines are often used in remote locations where access to power is limited, and they must perform reliably in all weather conditions, from the heat of summer to the freezing cold of winter.

A high-performance starter is key to ensuring that farmers can rely on their equipment during crucial harvests or planting seasons.

4. Marine Applications

In marine industries, such as large ships, cargo vessels, and offshore platforms, heavy duty starters are used to power the high-output diesel engines that drive these vessels. Marine environments are particularly harsh, with engines subjected to saltwater exposure, high humidity, and extreme weather conditions.

Heavy duty starters ensure that these engines start up reliably, even in adverse conditions, preventing delays or malfunctions that could lead to costly downtime or safety hazards at sea.

5. Backup Power Systems (Backup Generators)

Industrial-grade backup generators use heavy duty starters to ensure reliable startup in emergency power systems. These generators are critical in hospitals, data centers, factories, and other facilities that need uninterrupted power.

A heavy duty starter ensures that generators kick in quickly when the main power supply fails, providing a seamless transition and minimizing operational disruptions.

Each of these industries depends on heavy duty starters to keep operations running smoothly, reliably starting engines even under the most challenging conditions.

Whether it’s for heavy trucks, construction machinery, agricultural equipment, marine vessels, or backup power systems, the right starter is crucial for ensuring reliability and minimizing downtime.

Part 4. Why Choose Cqstart Spring Starter for Heavy Duty Engine?

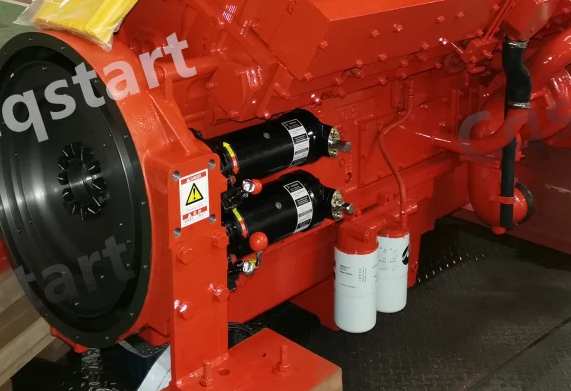

Cqstart spring starter is an efficient and environmentally friendly solution for starting heavy-duty diesel engines, specifically designed to handle a variety of harsh working conditions.

It offers the following significant advantages and is suitable for heavy equipment such as trucks, construction machinery, ships, military vehicles, and backup generators:

No Battery, Maintenance-Free, Suitable for Harsh Environments

One of the biggest advantages of the Cqstart spring starter is that it does not rely on batteries or external air sources. It uses a spring energy storage system to start the engine, avoiding common issues like battery aging and charging problems, greatly reducing maintenance costs.

Especially in harsh environments such as mining areas, ships, and remote job sites, the spring starter performs exceptionally well. It is not affected by extreme temperatures or high humidity, consistently providing powerful starting torque for diesel engines.

High Torque Output, Easily Starts Large Displacement Diesel Engines

Cqstart spring starter is specifically designed for large-capacity diesel engines, supporting engines up to 50L in displacement, setting a world record for spring-powered starting.

It provides efficient and rapid starts, ensuring that equipment can be put to work at any time, reducing downtime and increasing operational efficiency.

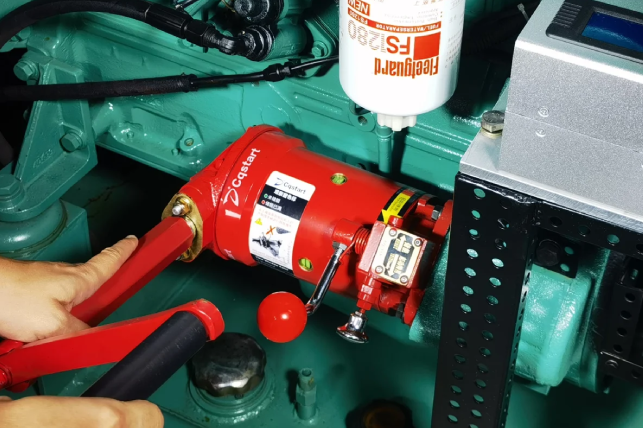

Compact Design, Easy Installation, Compatible with Multiple Devices

Cqstart spring starter’s compact design allows it to fit a wide range of equipment and simplifies the installation process. Without the need for complex electrical or pneumatic systems, installation time and costs are significantly reduced.

Whether installing on new equipment or replacing older starters, the spring starter can be quickly installed and put into operation, greatly enhancing equipment availability.

Low Failure Rate, Strong Durability, Reduces Maintenance Costs

Compared to traditional electric starters, the Cqstart spring starter has a lower failure rate and stronger durability. With no batteries or electrical systems, it avoids common problems like battery aging and short circuits, resulting in a longer lifespan.

Using the Cqstart spring starter helps reduce maintenance frequency, lower repair costs, and save significant operational expenses.

Cqstart spring starter is an ideal solution for various heavy-duty diesel engine applications. Whether in harsh environments, for frequent starts, or for low maintenance costs, Cqstart spring starter provides stable and reliable performance, making it the best choice for your equipment’s operation.

In Summary

The choice of a heavy-duty diesel engine starter is crucial, as different types of heavy-duty starters are suited for different working conditions. Spring starter is a reliable, battery-free starting solution, particularly suitable for extreme environments, emergency generators, and remote equipment.

If you’re looking for a durable, efficient, and environmentally friendly heavy-duty starter, Cqstart spring starter is the best choice for you!

FAQs about Heavy Duty Starter

1. Which is better, high torque or low torque?

The choice between high torque and low torque depends on the specific requirements of the application. High torque is generally better for heavy-duty tasks, such as starting large engines or operating machinery under high load conditions, as it provides more power to overcome resistance.

On the other hand, low torque is suitable for lighter applications where less power is required, offering smoother and more energy-efficient operation. Ultimately, the “better” option depends on the specific needs, load demands, and operational environment of the equipment.

2. Does starter motor affect performance?

Yes, the starter motor impacts engine performance. A reliable starter ensures smooth starts, while a faulty one can cause slow cranking or failure to start, affecting overall engine efficiency and performance. Regular maintenance is key to keeping it working well.

3. How to use a heavy duty starter?

Using a heavy-duty starter, like a spring starter, is simple and efficient. First ensure that the spring is properly wound and stored with sufficient energy. Once ready, engage the mechanism to release stored energy, which then turns the engine’s flywheel, initiating the start.