The starter is one of the essential components in modern machinery and vehicles. Its primary function is to start the engine from a stationary state and ensure smooth operation. In this post, we will delve into the how does a starter work, along with other relevant information. Let’s take a look!

Part 1. What is a Starter?

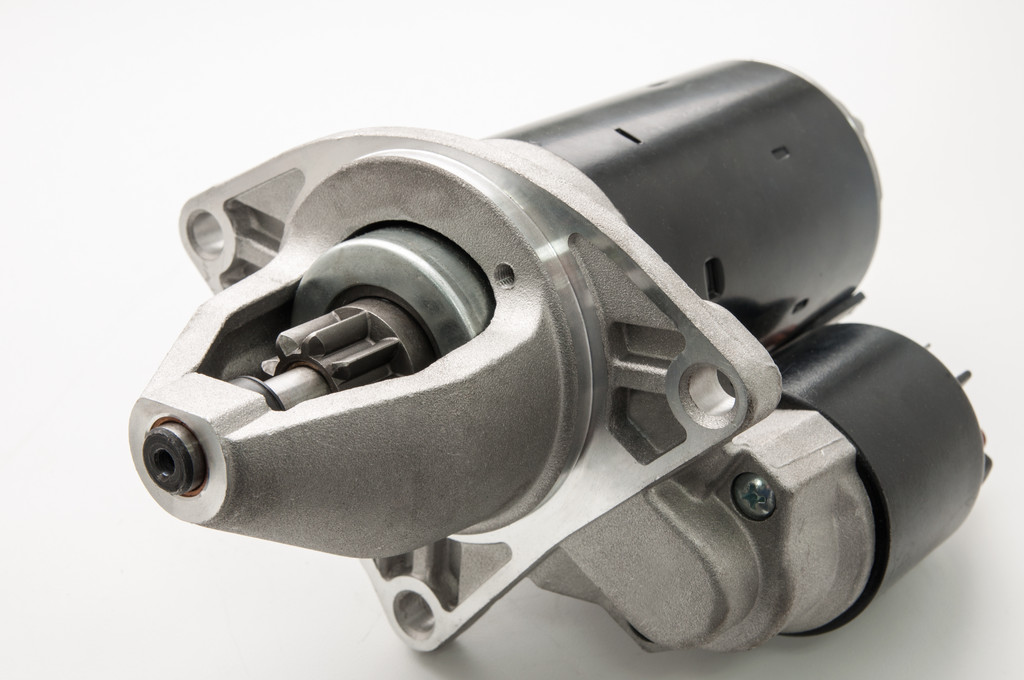

A starter is a device that provides initial power to start an internal combustion engine. The most common type we encounter in daily life is the electric starter, which uses a battery to power an electric motor that turns the engine’s flywheel.

However, there are also other types, such as spring starters and air starters. These starters are crucial in various applications, especially where electrical power is unreliable or special conditions are required.

Part 2. Key Components of a Starter

While the starter motor is often referred to simply as the “starter,” it actually refers to a system of components that work together to start an engine. The system includes the battery, ignition switch, relay, solenoid, and the starter motor itself.

To understand how a starter works, it’s helpful to look at the key components that make up the starter system.

Battery: The battery stores electrical energy that powers the starter motor. A charged battery is crucial for providing the necessary power to start the motor.

Ignition Switch: When you turn the key in your ignition, it activates the ignition switch, sending a signal to the starter relay to power the starter motor.

Solenoid: The solenoid is an electromagnetic switch that pushes the starter gear, or pinion, forward so it can engage with the flywheel. It also carries a significant amount of electrical current to the motor.

Starter Relay: This component acts as a switch that connects the battery to the starter motor. When the ignition switch is turned on, the relay closes the circuit, allowing the battery’s power to reach the starter motor.

Starter Motor: This is the core component that converts electrical energy from the battery into mechanical energy. The starter motor rotates the flywheel to start the engine.

Flywheel: The flywheel is a heavy, rotating disk connected to the engine’s crankshaft. The starter motor engages with the flywheel to turn it and start the engine.

Part 3. How Does a Starter Work?

In the vehicles, ships, and heavy machinery we use daily, the traditional starter is mostly based on an electric motor, therefore, here we mainly introduce the working principle of electric starter as follows:

Step 1: Turning the Ignition Key

When you turn on the ignition key (or press the start button in modern vehicles), the ignition switch sends a signal to the starter relay. This tells the relay to close the electrical circuit between the battery and the starter motor.

Step 2: Activating the Solenoid

The solenoid, an electromagnetic switch, is activated by the electrical current flowing from the battery. The solenoid pushes the starter gear (pinion) forward, engaging it with the engine’s flywheel. Gear engagement is crucial for the starter motor to be able to rotate the engine.

Step 3: Starter Motor Engagement

Once the solenoid engages the starter gear with the flywheel, the starter motor receives full electrical current from the battery. The motor starts rotating, which turns the flywheel and starts the engine. The force generated by the starter motor propels the engine to initiate its first compression cycle.

Step 4: Engine Starts Running

As the flywheel turns, the engine begins its own internal combustion process, which powers the vehicle. The starter motor is only required during the initial stages of starting the engine. Once the engine starts running, it produces its own power to continue operating, and the starter motor disengages from the flywheel.

Step 5: Disengagement of Starter Gear

Once the engine is running, the solenoid retracts, and the starter gear is disengaged from the flywheel. The starter motor then shuts down as its function has been completed.

Part 4. Challenges & Limitations of Starters

Although traditional electric starters are widely used, they may still face challenges under certain conditions, mainly in the following ways.

Insufficient Battery Power: Traditional starters rely on the battery for power. If the battery is low or running low, the starter may not properly start the engine.

Wear and Tear of Starter Components: Parts like gears and motors in electric starters may wear out over time, leading to rough starts or engine failure.

Environmental Factors: In extreme weather conditions (such as cold environments), the performance of the battery can be affected, causing the electric starter to lack sufficient starting power.

These issues limit the reliability of traditional starters in certain scenarios, particularly in devices that require frequent starts or where battery replacement is difficult or impossible.

Part 5. Spring Starter: A Reliable Alternative

As previously mentioned, there are other types of starters. And spring starters have been gradually gaining popularity as an alternative solution to overcome the limitations of electric starters.

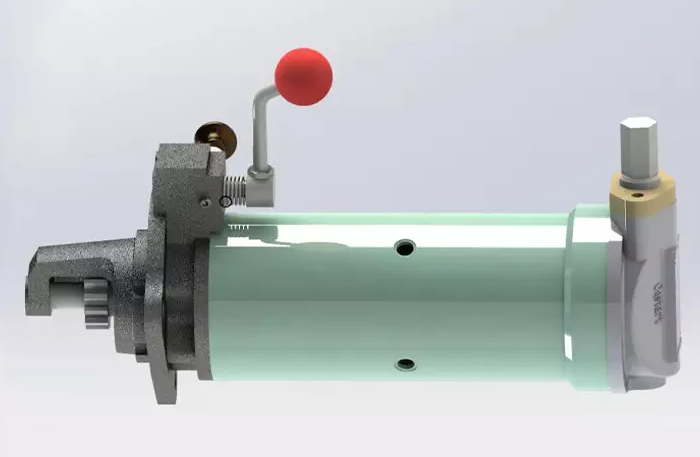

Unlike traditional starters, spring starters do not rely on batteries but instead use the energy storage principle of springs to start the engine through a mechanical system.

The working principle of a spring starter is relatively simple. When the spring inside the starter is compressed, it stores a large amount of potential energy. During startup, the compressed spring releases its energy, causing the gear to engage with the engine’s flywheel and start the engine.

The entire process is mechanically driven, so the spring starter is unaffected by battery power, ensuring reliable starting even when the battery is low or the power supply is unstable.

Advantages of Spring Starter

Compared to traditional electric starters, spring starters have several unique advantages, particularly in certain applications where they demonstrate stronger reliability and adaptability. Here we will take Cqstart Spring Starter as an example to introduce the key benefits of spring starters.

Compact Design and High Adaptability

Cqstart spring starter features an independent working system that requires no external support and operates solely through manual power. Its mechanical structure ensures stable performance in extremely high or low-temperature environments, making it highly adaptable to various conditions.

Maintenance-Free and Environmentally Durable

It is designed for optimal lubrication, anti-corrosion properties, and no need for maintenance, offering extremely low operating costs. Its eco-friendly coating and robust internal mechanical structure provide protection against water, oil, and salt spray, ensuring long-lasting durability.

Safe and Reliable

With its pre-engagement and explosion-proof design, it is suitable for hazardous environments and completely avoiding spark risks. Additionally, the product contains no liquid grease or magnetic components, meeting safety standards for special scenarios such as air transportation.

Easy Operation and Quick Installation

The spring starter is equipped with standard SAE mounting interfaces and requires only screws for installation. It is simple to operate, completing one cycle in 30 seconds, while smaller models take just 10 seconds.

Cost-Effective

With no additional system equipment such as compressors, hydraulic units, or storage tanks, the overall system cost is significantly lower than traditional hydraulic or pneumatic starting systems, offering outstanding cost-efficiency.

Wrap Up

Starters are vital for machinery and vehicles, ensuring smooth engine ignition. While electric starters struggle with low batteries or extreme conditions, spring starters provide a reliable and battery-free solution, even in harsh environments.