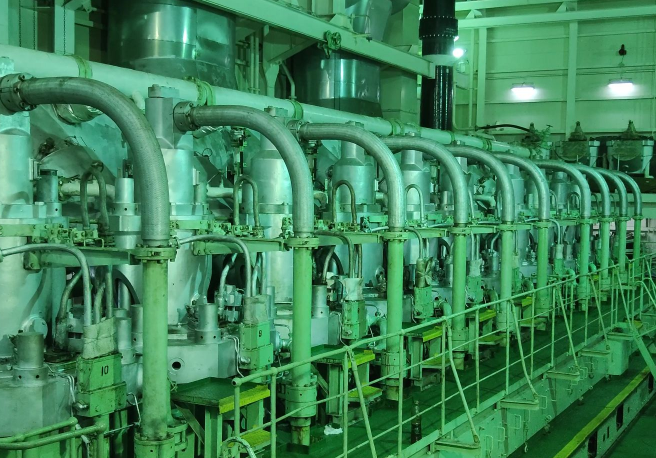

Do you think starting a ship main engine is as simple as starting a car? In reality, the situation is far more complex. Ship engines are typically much larger and more intricate than car engines, and they carry much more critical safety responsibilities. So, how to start a ship engine? Keep reading, we will provide the answers for you in this post.

Part 1. Different Types of Ship Engine Start Systems

Before diving into the details of how to start a ship’s engine, it’s important to first understand the different types of marine engine start systems. These systems vary based on the ship’s specific needs, environmental conditions, and technical requirements. The main types of starting systems are electric start systems, air start systems, and mechanical start systems.

Electric Start Systems

This is the most common starting method for modern ships, suitable for high-power engines. The electric starter uses batteries to provide energy to start the engine. However, it may face issues if the power supply is insufficient or if the battery fails.

Air Start Systems

Air starters use compressed air to start the engine and are typically used on certain types of ships. While reliable under heavy load, Air systems require additional compressors and stability of the air supply may become an issue when operating at sea.

Mechanical Start Systems

For some ships, especially those in areas where electrical or air supply is inadequate, mechanical start systems (such as spring starter) provide a reliable starting method. A spring starter uses mechanical energy to store energy, allowing for engine start support without electrical power.

Part 2. Steps to Start a Ship Engine

Starting the ship’s engine is a critical procedure to ensure its safety and efficiency. To avoid any startup failures, you should take the steps carefully. In case of electrical system or other starting system failures, backup methods such as the spring starter can be used to ensure a smooth engine start.

The following are the detailed steps to follow when starting a ship’s engine:

1. Pre-Start Checks

Before starting the ship’s engine, a comprehensive inspection must be done to ensure all systems are functioning properly. This helps prevent issues during the startup process. The pre-start checks include:

Fuel System Check:

- Fuel Supply: Ensure there is sufficient fuel and that there are no leaks. Check the fuel pipes for blockages, and verify that the fuel pump is working properly.

- Fuel Quality: Ensure the fuel is free from contamination, especially if the vessel has not been used for a long period. Avoid sediment or water entering the engine.

Lubrication System Check:

- Oil Level: Ensure the engine oil level is adequate and the oil is clean. Low or dirty oil can impair the engine’s lubrication and lead to overheating or damage.

- Oil Pressure Check: Check the oil pressure gauge before starting to ensure it is within the normal range.

Cooling System Check:

- Coolant Level: Check the coolant level to ensure the cooling system will function properly and prevent engine overheating.

- Water Pump Check: Ensure the water pump is working properly, and there are no blockages in the cooling circuit.

Electrical System Check:

- Battery Voltage: Verify the battery voltage is sufficient for the electric starter system to function.

- Cable Connections: Ensure the battery cables and starter connections are secure to avoid interruptions in power delivery.

Air System Check (if applicable):

- Air Pressure Check: If the ship uses a Air starter system, ensure the compressed air supply is sufficient and stable.

2. Startup Procedure

Once the pre-start checks are completed, the crew can proceed with starting the engine by following these steps:

Set the Control System:

- Pre-Start Settings: Based on the ship’s engine type and control panel design, set the proper startup mode. Most modern ships have digital control panels, where you simply press the start button to activate the electric starter.

- Control Panel Check: Make sure all switches, buttons, and control levers are in the correct positions. For example, the start switch should be in the “Start” position, and the throttle and gear levers should be in neutral.

Start the Electric System:

- If the ship uses an electric starter system, press the start button or turn on the start switch. The battery will provide power to the electric starter, and the engine should start smoothly.

- During the startup process, monitor the engine’s indicators to ensure voltage, current, pressure, and RPM are within normal ranges. If any abnormalities are detected, immediately stop the engine and check for issues.

Switch to Backup Start System:

- In Case of Electric System Failure: If the electric starter fails to start the engine (e.g., due to low battery or electrical system issues), switch to a backup starting system immediately.

- Use Air Starter (if applicable): If the ship has a Air starting system, check the air pressure and then activate the Air starter.

- Use Spring Starter: If both the electric and Air systems fail, use the spring starter. Manually wind the spring starter to store mechanical energy, then release it to start the engine using the spring force.

3. Post-Start Monitoring

After the engine starts, the crew should continuously monitor its operation to ensure it runs smoothly without any issues.

Monitor Engine Temperature: After startup, check the engine temperature immediately to ensure it remains within the normal range. An overheating engine could indicate a problem with the cooling system.

Monitor Engine Pressure: Check the engine oil pressure and coolant pressure. Low oil pressure or coolant pressure may indicate a system fault that could damage the engine.

Observe Engine Noise and Vibration: Pay attention to any unusual engine noise or vibration. Abnormal sounds or vibrations could signal a malfunctioning component, and the engine should be shut down for inspection.

Check Emissions and Smoke: Inspect the exhaust system for any abnormal smoke or gas emissions. If unusual emissions are detected, it may indicate issues with the fuel system, combustion system, or exhaust system.

4. Troubleshooting Startup Issues

If issues occur during the engine start process, here are some common problems and their solutions:

Low Battery Power: If the battery is too low to start the electric system, use a spring starter or Air starter as a backup.

Fuel Supply Issues: If the fuel system is malfunctioning, check the fuel filters, pumps, and fuel lines for blockages or damage. Clean or replace the components to restore normal fuel flow.

Lubrication System Problems: If the oil pressure is too low during startup, check the oil pump and oil lines for blockages or faults.

Air System Failure (if applicable): If the Air system is unable to generate enough air pressure, check the compressed air storage system to ensure it is full, and inspect the air lines for leaks.

5. Concluding the Startup Process

Once the engine has successfully started and is operating smoothly, the crew should ensure that all control systems remain in proper working order and proceed with regular operational procedures. Regularly monitor the engine’s performance to maintain optimal operating conditions throughout the voyage.

Part 3. Common Issues During Ship Engine Start & Solutions

During the engine start process, common issues include insufficient battery power, unstable start currents, and fuel supply problems. Here are some common issues and their solutions:

Insufficient Battery Power

If the ship relies on an electric starter and the battery is low, the engine may not start. In this case, a spring starter can serve as a backup. By manually winding the spring, you can store enough mechanical energy to start the engine.

Unstable Start Current

Electrical instability may cause the engine to fail to start. If there is a problem with the electric start system, using the pneumatic starter or the spring starter can serve as effective alternatives.

Fuel Supply Issues

If there’s an issue with the fuel system, first check the fuel filter, pump, and lines to ensure fuel can flow smoothly into the engine.

In such situations, the spring starter provides a critical backup. In the event of an electrical system failure or pneumatic system malfunction, the spring starter can provide stable starting power and ensure the ship’s engine starts promptly, preventing long periods of downtime.

Part 4. Why is the Backup Start System Necessary?

Regardless of whether the starting system is electric, pneumatic, or mechanical, it is vital to have a reliable backup. Ships typically operate on long voyages, and any startup failure can lead to extended downtime, affecting the schedule and safety. A backup starting system provides peace of mind and ensures that the engine can start smoothly in any circumstance.

The spring starter, like Cqstart spring starter, as a mechanical backup solution, is particularly effective when there is no power supply. It is not dependent on batteries or air compressors and is simple in design, with low maintenance costs. It is suitable for various types of ships.

In Conclusion

Starting the ship engine is a key step in ensuring smooth sailing. However, its startup is relatively complicated, so during the operation, you should always pay attention to the various indicators of the engine. If you encounter a situation where the engine cannot start, you can consider using a spring starter to help you solve the startup problem.