Old small engines that have been left unused for a long time often refuse to start. Whether it’s a portable generator, a mini diesel engine, or a small water pump, running into issues like a stuck pull cord, an unresponsive crank, or failure to ignite can be incredibly frustrating.

So, how to start an old small engine that won’t start? Here we will guide you through a practical set of steps and tips to help you troubleshoot and bring these long-dormant machines back to life.

Part 1. Common Reasons: Why Won’t an Old Small Engine Start?

Understanding these common causes is the first step toward effective troubleshooting and repair. Here’s a closer look at the most common reasons why an old small engine might refuse to start. Let’s go!

1. Stale or Degraded Fuel

Gasoline left sitting in the fuel tank for more than a month can start to degrade. Over time, it oxidizes and may absorb moisture from the air, resulting in a watery, varnish-like substance that no longer burns efficiently. This poor-quality fuel can clog fuel lines and prevent proper combustion, making it impossible for the engine to start.

2. Clogged Carburetor

One of the most frequent issues with unused small engines is a blocked carburetor. Residue and deposits from old fuel can clog carburetor jets or fuel passages.

When this happens, the engine can’t draw in the proper amount of fuel needed for ignition, leading to hard starting or no starting at all.

3. Faulty or Dirty Spark Plug

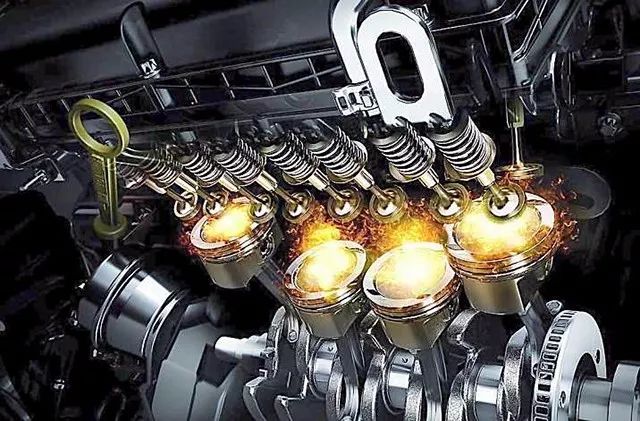

The spark plug is crucial for igniting the air-fuel mixture. If it’s fouled with carbon deposits, has an overly wide spark gap, or electrodes are worn out, it may not produce a strong enough spark—or any spark at all. This can lead to misfires or a complete failure to start.

4. Dirty or Blocked Air Filter

An air filter that’s clogged with dirt, dust, or debris can significantly restrict airflow into the engine. Insufficient air disrupts the optimal air-fuel ratio, which can prevent the engine from firing up. Regular maintenance of the air filter is essential for reliable starting.

5. Starter Mechanism Failure

The starting system itself may be the problem. If the recoil starter rope won’t retract, the electric starter doesn’t respond, or a spring starter (common in some diesel engines) has weakened over time, the engine won’t turn over properly. Without a reliable way to crank the engine, ignition can’t happen.

6. Lack of Compression

Internal engine wear can also be to blame. If the piston rings are worn out or the cylinder has leakage due to aging seals or gaskets, the engine may lose compression. Without sufficient compression, the fuel-air mixture cannot be compressed properly, which is critical for ignition and power generation.

Part 2. How to Start an Old Small Engine That Won’t Start?

Getting an old small engine up and running again can be a rewarding process if you follow the right steps. Here’s a detailed guide to help you revive your dormant equipment safely and effectively:

Step 1. Safety Precautions Before Starting

Before you begin any work, make sure to follow these safety measures:

- Ensure the equipment is operated in a well-ventilated area to prevent carbon monoxide poisoning.

- Wear work gloves and safety goggles to protect yourself from grease and potential injuries from moving parts.

- Inspect the fuel tank and surrounding areas for any fuel leaks to reduce the risk of fire.

Step 2: Replace the Old Fuel

Drain any remaining fuel from the tank, as old gasoline or diesel can degrade and cause starting issues. After draining, clean the tank to remove residue or water buildup.

Refill it with fresh fuel—preferably one mixed with a fuel stabilizer to improve combustion and prevent further degradation during storage.

Step 3: Inspect the Spark Plug

Remove the spark plug and check the condition of the electrodes:

- If there’s carbon buildup or oil fouling, clean the plug using a wire brush.

- For severely worn or damaged plugs, replace them with a new one.

- Check the spark gap—this should typically be between 0.6 to 0.7 mm. Use a feeler gauge to ensure it’s set correctly, as improper gaps can cause misfires or failed ignition.

Step 4: Clean the Carburetor

Remove the carburetor carefully and spray it thoroughly with a carburetor cleaner. Pay special attention to:

- The jets and fuel passages—these often become clogged due to fuel residue.

- If cleaning doesn’t restore proper fuel flow, consider installing a carburetor rebuild kit, which includes replacement parts like gaskets, floats, and jets.

Step 5: Replace or Clean the Air Filter

The air filter plays a vital role in maintaining the correct air-fuel ratio. Depending on the type:

- Foam filters can be washed with soapy water, dried completely, and re-oiled if required.

- Paper filters should be replaced entirely if they appear dirty or damaged.

- A clean air filter ensures smooth airflow and enhances ignition efficiency.

Step 6: Inspect the Starting Mechanism

Different engines use different starting methods—each should be checked to ensure it functions properly:

Recoil (pull-start) system: Make sure the cord pulls smoothly and retracts fully. If it’s stuck or doesn’t spring back, the recoil assembly may need servicing.

Electric starter: Check if the battery has enough charge and whether the starter motor engages when the switch is pressed. A weak battery or faulty solenoid can prevent engine turnover.

Spring starter: For engines equipped with a spring starter, ensure the spring is fully wound and the release mechanism is functioning. Spring starters are particularly useful for off-grid applications or older machines that don’t have electrical systems.

Part 3. Cqstart Spring Starter: Better Solution for Starting a Small Engine

For older engines without electric start systems, a spring starter offers a compact, battery-free, and low-maintenance solution. Users simply wind the starter manually; once released, the stored energy in the spring rapidly turns the engine’s crankshaft to initiate ignition.

This method eliminates the risk of battery failure and is especially well-suited for remote, off-grid, or extreme weather environments.

Cqstart 7 Series Spring Starter is the most compact and lightweight, designed specifically for diesel engines under 2 liters.

Weighing only 11 kg, the 7 Series is currently the lightest spring starter available on the market, making it a game-changer for space-constrained applications like offshore platforms, marine equipment, and portable machines.

Despite its small size, it delivers strong and reliable ignition power, completely independent of batteries or external electrical systems.

Key Advantages of the Cqstart 7 Series Spring Starter:

Lightest-in-Class: At just 11 kg, it’s the lightest spring starter for sub-2L diesel engines, reducing the overall burden on compact setups.

Designed for Tight Spaces: Ideal for use where space is limited—perfect for offshore platforms, boats, or emergency diesel systems.

Built to Endure: Waterproof, salt-spray resistant, and tested to withstand high and low temperatures, the 7 Series excels in extreme environments.

No Electricity Needed: Functions purely mechanically, eliminating concerns about battery failure or wiring issues.

If you’re looking for a reliable, low-maintenance starting system for your small diesel engine, the Cqstart 7 Series Spring Starter delivers unmatched performance where other methods fall short.

Part 4. Still Won’t Start? It Might Be Time for Professional Help

If you’ve gone through all the steps—replacing fuel, cleaning the carburetor, checking the spark plug and starter system—but your small engine still refuses to start, the issue may be more serious than it appears. In such cases, internal mechanical problems could be the root cause, including:

Low Cylinder Compression

Worn piston rings or valve seal issues can lead to a significant drop in compression, making it difficult or impossible for the engine to ignite the fuel-air mixture.

Ignition Timing Problems

If the timing is off due to a slipped timing belt, worn camshaft, or faulty ignition components, the spark may not occur at the right moment, preventing combustion.

Internal Damage to Crankshaft or Pistons

Long-term storage, poor lubrication, or previous mechanical failure may have led to damage within the crankshaft, pistons, or connecting rods—issues that are not easily detected without proper tools.

Attempting to force-start an engine with these kinds of problems can lead to more extensive and costly damage. That’s why it’s highly recommended to take the engine to a qualified technician for a full inspection and repair. With professional diagnosis, you’ll save time, protect your equipment, and ensure a safer and more effective recovery of your engine.

Part 5. How to Prevent Future Starting Problems?

To avoid the frustration of engine startup issues in the future, especially with older or infrequently used small engines, consider adopting these preventative maintenance habits:

Start the Engine Regularly

Even if you don’t need to use the equipment, starting it once a month and letting it run for a few minutes helps circulate oil, lubricate internal parts, and maintain the fuel system. This simple step can significantly reduce the chances of internal corrosion or fuel system gumming.

Drain Fuel Before Long-Term Storage

When storing the engine for more than a few weeks, always drain the fuel tank completely. Old fuel tends to degrade, oxidize, or absorb moisture, which can clog the carburetor or prevent ignition.

Change Oil and Spark Plugs Regularly

Keep up with oil changes and inspect the spark plug for deposits or wear. A clean spark plug and fresh oil not only ensure smoother starts but also prolong the engine’s lifespan.

Install a Spring Starter

For equipment used in remote or unstable environments, consider switching to a spring starter like the Cqstart 7 Series Spring Starter. It eliminates the need for a battery, reduces the risk of electrical failure, and provides a reliable ignition method for long-stored engines.

Wrap Up

Bringing an old small engine back to life is easier when you know what to check and how to fix it. From fresh fuel and clean spark plugs to reliable solutions like the Cqstart Spring Starter, each step helps ensure smoother starts, especially in remote or power-limited environments.

Don’t forget: regular maintenance, monthly startups, and proper storage are the best ways to keep your engine running strong for the long haul.