The emergency fire pump is the guardian of buildings and industrial facilities. When the fire alarm goes off, starting the fire pump becomes crucial as it determines the speed and effectiveness of the fire response.

So, in the face of such an urgent situation, how to start emergency fire pump? What if the fire pump fails to start? Don’t worry, in this article, we will provide a step-by-step guide to ensure accuracy in critical situations and help you handle fire emergencies with confidence!

Part 1. What is Emergency Fire Pump?

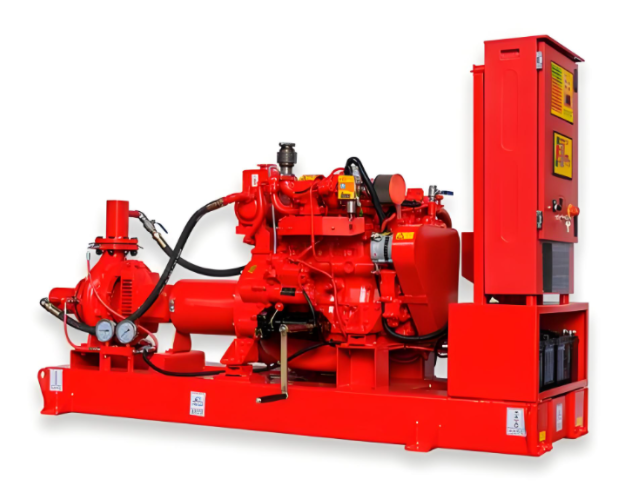

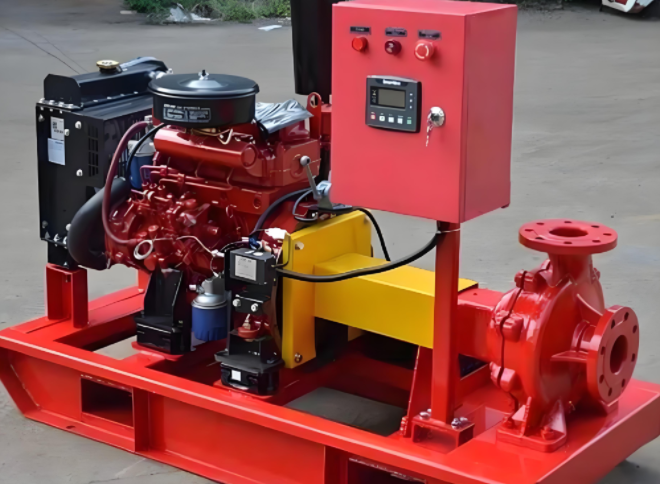

Emergency fire pump is a highly efficient water pump designed specifically for fire emergencies. Its primary function is to transport water through pipelines to the fire scene, supplying water to sprinkler systems or other firefighting equipment. It is one of the core components of a fire protection system, capable of providing timely, high-pressure water to quickly control the spread of fire.

Basic Components of an Emergency Fire Pump:

- Pump Body: The mechanical part that generates the water flow, typically made from corrosion-resistant materials.

- Motor or Engine: The electric motor or diesel engine that drives the pump body.

- Control System: Used to start, stop, and monitor the pump’s operation.

- Water Source Interface: The connection to the water source, typically a water tank or tower.

- Pump and Sprinkler Pipelines: The system that carries water from the pump to the firefighting area.

Emergency fire pumps are typically installed in fire control rooms or pump houses, ensuring that they can be quickly activated and provide necessary water flow during a fire.

Part 2. How to Start the Emergency Fire Pump?

When starting the emergency fire pump, it’s essential to follow the operating procedure carefully to ensure each step is performed correctly. Here is a detailed guide on how to start the fire pump:

Step 1: Check Equipment Status

Before starting the fire pump, a thorough inspection of each component is required to ensure the equipment is in good working condition. Check the following:

- Power and Fuel: Ensure the power supply to the fire pump is functioning properly. If it is electrically driven, make sure the electrical connections are secure. For diesel or gasoline-driven pumps, check if the fuel is sufficient and that the fuel lines are clear.

- Water Source: Verify that the water source is adequate and unobstructed. If the pump depends on an underground water tank or water tower, ensure the water level is normal.

- Pump and Piping: Inspect the pump body and water pipes for any signs of damage, such as leaks, cracks, or wear. Damaged components may affect the water flow.

- Control Panel: Check the control panel’s electrical system, including power indicators, alarm lights, and pressure gauges, to ensure there are no faults.

Step 2: Start the Power Supply

The procedure for starting the power supply varies depending on the type of fire pump:

- Electric-Driven Fire Pump: Ensure the power switch is in the “on” position, then press the power start button to start the motor. If in automatic mode, the motor will start automatically.

- Diesel-Driven Fire Pump: Check the diesel engine’s fuel system to ensure sufficient fuel. Press the start button to activate the diesel engine and monitor whether it runs smoothly. Note: If there are issues with the power or fuel system, contact maintenance personnel immediately for repairs.

Step 3: Start the Fire Pump

Once the power is activated, the next step is to start the pump and water flow system. Follow these procedures:

- Start the Pump: Depending on the pump’s control system, choose the appropriate start mode. There are typically two modes: automatic and manual. In automatic mode, the pump will start automatically when the fire alarm is detected. In manual mode, the operator must press the start button to activate the pump.

- Adjust Pump Pressure and Flow: On the control panel, adjust the water flow rate and operating pressure to ensure the pump’s output meets the required specifications. Generally, the pump’s pressure should meet the minimum water pressure required by the fire system to ensure proper operation of the sprinkler system.

Step 4: Confirm the Pump is Operating Normally

After the pump starts, it’s crucial to verify that the fire pump is working correctly. This can be checked by:

- Check Water Flow: Ensure the water is flowing smoothly and the water pressure is adequate. If the pump fails to provide the expected water flow, there may be an issue with the water source or the pump.

- Check Pump Condition: Listen for unusual sounds from the pump during operation, such as grinding or abnormal noises. If strange sounds are heard, the pump may be malfunctioning.

- Monitor Pressure Gauge: Check the water pressure output from the pump to ensure it is stable and meets the required standards.

Step 5: Continuous Monitoring and Maintenance

After the pump is started, continuous monitoring of its operating status is necessary to ensure it operates smoothly. Check the water flow, pressure, and pump temperature to ensure the system is functioning correctly. Regularly clean the pump’s filter and inspect the pipes for blockages to avoid malfunction due to insufficient maintenance.

During the duration of the fire, operators should regularly inspect the fire pump to ensure it continues to provide adequate water flow until the firefighting efforts are complete.

Part 3. Common Troubleshooting for Emergency Fire Pumps

During operation, emergency fire pumps may encounter some common issues. Here are some common problems and troubleshooting methods:

1. Pump Fails to Start:

- Check the Power Supply: Ensure the power supply is properly connected.

- Verify Fuel System: Confirm that there is enough fuel in the system.

- Check the Control Panel: Make sure the start signal is being transmitted correctly.

- For Diesel Pumps: Check if the diesel engine start button has been pressed and ensure the fuel lines are clear.

2. Insufficient Water Flow:

- Check Water Source: Ensure the water source is adequate, and the water level in the tank or tower is not too low.

- Inspect Inlet Pipes: Check for blockages in the intake pipes to ensure proper water flow.

- Check for Air or Debris: Ensure the pump is not obstructed by air or debris, which may prevent it from drawing water properly.

3. Unstable Water Pressure:

- Check Control Panel: Ensure the pump’s water pressure settings are correct.

- Inspect Pump for Leaks: Look for any leaks in the pump body or unstable pipe connections that may affect pressure.

4. Unusual Noise or Vibration:

- Listen for Abnormal Sounds: If unusual noises are heard, stop the pump immediately and inspect it.

- Check Mechanical Parts: Inspect the pump shaft, bearings, and other mechanical components for wear or looseness.

Part 4. How to Fix Emergency Fire Pump Can’t Start Quickly?

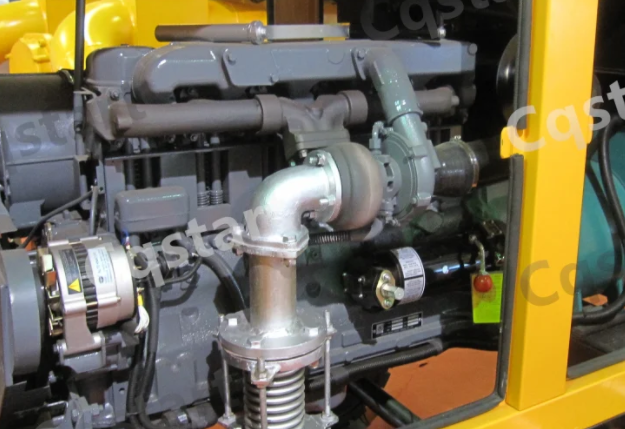

In emergency situations, if the emergency fire pump fails to start, it could lead to serious safety hazards. Therefore, it is critical to address this issue promptly and effectively. As we mentioned before, common causes include power failure, insufficient fuel, mechanical issues, and more. To ensure the pump is ready for use during a fire, additional equipment may be needed to resolve startup issues. Spring Starter is an effective solution in such cases.

Spring Starter is a mechanical device commonly used in diesel engine starting systems, particularly in scenarios where external power sources or batteries cannot be relied upon. The working principle involves storing energy in a spring, which is then released to provide the necessary startup power. It is fast, efficient, and reliable, making it ideal for providing startup energy to an emergency fire pump in critical situations.

Main Features of the Spring Starter:

- No External Power Source Required: The spring starter does not require batteries or electrical power supply. It operates purely on mechanical energy to start the engine without battery, making it ideal for environments where electrical systems cannot be depended on.

- High Reliability: By storing energy in the spring, the spring starter can quickly release the energy when needed, providing reliable and rapid startup.

- Wide Environmental Adaptability: It operates effectively in extreme temperatures and harsh environments, making it perfect for emergency equipment like fire pumps.

How to Use a Spring Starter to Start an Emergency Fire Pump?

Step 1. Check the Condition of the Spring Starter

Before using the spring starter, ensure the spring is in good condition. Make sure the spring is not slack or damaged, and that the energy storage device is intact.

Step 2. Prepare the Equipment

Confirm that the spring starter is fully wound. Use manual or mechanical means to tighten or compress the spring to the required energy storage state. This process is usually done with a dedicated starting handle or device.

Step 3. Start the Emergency Fire Pump

Once the spring starter is ready, press the start button or pull the start handle to release the stored energy. The spring will quickly release its energy, transferring power through the drive mechanism to the engine of the emergency fire pump, thus starting the pump.

Step 4. Monitor the Pump Operation

After starting, observe whether the emergency fire pump is running normally. Check the water flow and pressure from the pump to ensure the system is providing the necessary water supply for firefighting.

Step 5. Post-Operation Maintenance

After using the spring starter, check for any abnormalities. Ensure the spring has fully returned to its initial state, ready for the next use. If any faults or issues are found, perform timely repairs or replacements.

Part 5. How to Maintain and Care Emergency Fire Pumps?

To ensure that the fire pump can start properly and provide a stable water supply in an emergency, regular maintenance and care are essential. Here are some basic maintenance recommendations:

- Regularly Inspect the Pump and Motor: Perform a thorough inspection every month or quarter to ensure that the pump and motor are free from any abnormal damage or wear.

- Clean the Filters: Regularly clean the pump’s filters to prevent impurities and sediment from blocking the pump, which could affect the water flow.

- Check the Fuel System: For diesel-powered fire pumps, regularly inspect the fuel system to ensure there is enough fuel and that the fuel lines are not blocked.

- Replace Wearable Parts: Regularly check and replace worn-out parts such as seals and bearings to ensure the equipment operates stably over the long term.

- Test the Control System: Periodically test the fire pump’s control and alarm systems to ensure they function reliably.

- Prepare a Backup Device: To quickly fix the fire pump failure problems, it’s necessary to prepare a backup device like a spring starter.

In Summary

The emergency fire pump is a core component of the fire emergency system, and ensuring its prompt startup during a fire is crucial. This article outlines the detailed steps for starting the emergency fire pump, common troubleshooting methods, and the application of the spring starter, helping you to better address any startup issues. Whether through conventional startup methods or using a spring starter when the pump fails to start, these measures ensure the fire pump operates at its maximum efficiency, safeguarding both lives and property.