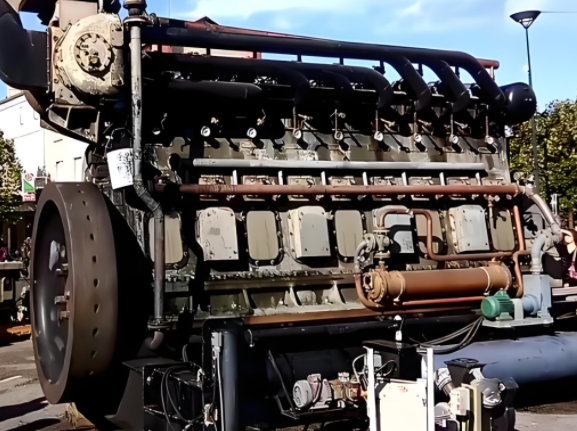

Large diesel engines are like steel giants, widely used in ships, industrial equipment, generator sets, and heavy machinery. Compared to smaller diesel engines, they are not only larger in size but also have a higher compression ratio, making starting the engine more challenging.

Choosing the right starting method not only ensures a smooth start to the engine’s “heartbeat,” but also extends its lifespan and ensures stable operation. In the following sections, we will explore the large diesel engines starting methods, common issues, and optimization strategies to keep them running at their best.

Part 1. How are Large Diesel Engines Started?

A large diesel engine starts by activating a starter system that begins turning the engine’s flywheel. As the engine rotates, air is drawn in, and fuel is injected into the combustion chamber. Due to the high compression inside the cylinder, the fuel ignites spontaneously, creating a powerful combustion process.

This combustion generates the energy needed to drive the engine, and once the engine reaches a stable running speed, the starter system disengages. The engine then continues running on its own, with the combustion process maintaining the engine’s operation.

Part 2. Main Challenges in Starting Large Diesel Engines

Starting a large diesel engine is no easy task, as various factors can hinder the process. From extreme temperatures to power system failures and fuel quality issues, understanding these challenges is crucial for ensuring reliable engine performance.

Impact of Low Temperatures on Starting

In cold environments, diesel fuel becomes more viscous and less fluid, reducing atomization efficiency of the fuel injection system. Additionally, engine oil thickens at low temperatures, increasing internal friction within the engine and making it harder to start.

Power System Failures

Many diesel engines rely on batteries for starting power. If the battery is undercharged, the electrolyte freezes, or the cables deteriorate, the starter motor may fail to provide sufficient torque, preventing the engine from turning over properly.

Air or Hydraulic System Failures

For diesel engines that use air or hydraulic starting systems, issues such as compressed air tank leaks or insufficient hydraulic pressure can result in startup failure. In air-start systems, condensation buildup in humid environments may freeze valves or clog nozzles, further hindering the process.

Fuel Quality Issues

Low-quality or long-stored diesel fuel may contain water or impurities, reducing combustion efficiency and making engine startup difficult. Additionally, using the wrong fuel grade for a given environment can negatively impact ignition and the combustion process.

Excessive Internal Engine Friction

After prolonged periods of inactivity, engine lubricant may settle, increasing friction between components. This added resistance can make it difficult for the crankshaft to rotate, ultimately affecting the starting performance.

Part 3. 4 Common Starting Methods for Large Diesel Engines

Depending on the application and power requirements, large diesel engines utilize different starting methods. The most commonly available options include electric, air, hydraulic, and spring starters, each with its own pros and cons. Below is a summary of the four starting methods, which will be discussed in detail in the following sections.

| Starting Method | Working Principle | Advantages | Applicable Scenarios |

| Electric Starter | Battery-powered motor drives the flywheel | Quick start, easy to use | Vehicles, generator sets |

| Air Starter | Compressed air drives a pneumatic motor to rotate the crankshaft | High torque, suitable for high-power diesel engines | Ships, industrial diesel engines |

| Hydraulic Starter | Hydraulic pump drives a hydraulic motor to start the engine | Stable operation, suitable for extreme environments | Mining, oilfield equipment |

| Spring Starter | Mechanical spring stores energy and releases it to drive the crankshaft | No power or air required, ideal for emergency starts | ATEX, marine, military, remote, harsh environments,emergency |

Way 1. Electric Starter

Electric starting relies on a battery-powered motor to drive the flywheel, initiating engine rotation. This method is commonly used in medium and small diesel engines, but for larger engines, it presents certain challenges:

Advantages:

- Simple and widely used in smaller diesel engines.

- Quick and convenient operation.

- Requires minimal additional equipment.

Disadvantages:

- Large diesel engines require high-capacity battery banks, which are costly and require frequent maintenance.

- Battery performance declines in low temperatures, reducing starting efficiency.

- Prolonged inactivity can lead to battery discharge, making emergency starts unreliable.

Way 2. Air Starter

Air starting systems use compressed air to drive pistons or turbine blades, which rotate the engine crankshaft. This method is popular in marine and industrial diesel engines, particularly in high-pressure environments.

Advantages:

- Delivers high torque, making it suitable for large-displacement engines.

- Independent of electrical systems, reducing reliance on batteries.

- Faster and more reliable in heavy-duty applications.

Disadvantages:

- Requires an additional air compression system, adding complexity and maintenance costs.

- In cold climates, moisture in the air system can freeze, leading to blocked valves or nozzle clogging.

- Limited air supply may restrict the number of startup attempts.

Way 3. Hydraulic Starter

Hydraulic starting systems use pressurized fluid to drive a hydraulic motor, which then turns the engine’s crankshaft. This method is particularly useful in extreme conditions, such as mining and marine applications.

Advantages:

- Provides stable and continuous torque, making it effective for large engines.

- Suitable for harsh environments where electrical and air systems may be unreliable.

- More compact and efficient than air starters in certain heavy-duty applications.

Disadvantages:

- Requires regular maintenance of the hydraulic system, including checking for leaks and maintaining pressure levels.

- Hydraulic fluid thickens in low temperatures, reducing system efficiency.

- Initial installation can be costly due to the need for high-pressure hydraulic components.

Way 4. Spring Starter

Spring starters use a mechanical energy storage system, where a heavy-duty spring is wound up and then released to drive the crankshaft. This method is ideal for remote or power-limited environments where traditional starting methods are impractical.

Advantages:

- No external power required: does not rely on electricity, batteries, or compressed air.

- Simple and low maintenance: fewer components mean lower operational costs and a longer service life.

- Reliable in harsh conditions: unaffected by extreme temperatures, moisture, or fuel quality issues.

- Ideal for emergency starts: provides a dependable backup option when other systems fail.

Disadvantages:

- Requires manual winding, which may not be suitable for all applications.

- Limited to specific engine sizes and configurations.

Why Spring Starter is Best for Starting Large Diesel Engine?

- No Batteries or Air Compressors Needed: Works without electricity, air, or hydraulics.

- Low Maintenance: Fewer components mean lower maintenance costs.

- Reliable in Extreme Conditions: Unlike batteries that lose charge in cold temperatures or air starters that freeze, spring starters function consistently in harsh environments.

- Cost-Effective: No need to replace batteries, maintain compressors, or manage hydraulic fluid.

Part 4. Cqstart – Best Spring Starter for Large Diesel Engine

If you want to start large diesel engines smoothly, especially those with massive displacement like 50 liters, then Cqstart spring starter is undoubtedly your best choice. Whether it’s a small diesel engine with a displacement as low as 2L or a heavy-duty engine with up to 50L, Cqstart spring starter can handle it effortlessly, with compatibility far exceeding that of competing products.

Why Cqstart Spring Starter?

Reliable Performance in All Environments

Cqstart spring starter delivers consistent performance in any environment, unaffected by weather conditions. Unlike electric or air starters, it doesn’t rely on external power sources, making it ideal for remote or extreme locations.

No External Power Source Needed

Operating on mechanical energy storage, the Cqstart spring starter doesn’t require batteries, air compressors, or hydraulic systems, making it perfect for emergency situations or areas with limited power access.

Low Maintenance and Cost-Effective

With fewer components and no need for battery or air compressor maintenance, the Cqstart spring starter offers lower operating costs and greater reliability compared to traditional starters.

Quick and Efficient Starting

The Cqstart spring starter ensures fast and efficient engine starts, saving time by eliminating the need to wait for compressors to build pressure or batteries to recharge.

Ideal for Heavy-Duty Diesel Engines

Designed for large, high-compression diesel engines, the Cqstart spring starter provides the high torque needed for heavy machinery, marine engines, power generation, and industrial applications.

Environmental Friendliness

Eco-friendly, the Cqstart spring starter eliminates reliance on fuel, electricity, or air, helping reduce emissions and waste in sensitive environments.

Part 5. How to Optimize the Starting Performance of Large Diesel Engines?

1. Choose the Right Starting Method

Electric starters are suitable for daily applications, but it is important to ensure regular maintenance and charging of the battery.

Air or hydraulic starters are ideal for high-power engines and require regular inspection of the air supply and hydraulic system pressure.

Spring starters are perfect for emergency starts and are especially important in environments without power or compressed air sources.

2. Optimization Measures for Cold Environments

Use fuel preheating systems to improve fuel atomization and enhance combustion performance.

Use oil preheaters to reduce the viscosity of the oil and minimize starting resistance.

Choose low-temperature diesel (e.g., winter diesel) to prevent fuel from solidifying.

3. Regular Maintenance of Batteries and Fuel Systems

Regularly check the battery charge, clean the terminal contacts, and prevent increased resistance.

Ensure the fuel system is clean, regularly replace the diesel filter, and prevent water and impurities from affecting combustion.

4. Backup Spring Starter as an Emergency Solution

Spring starters do not require external power or air and can serve as a reliable backup starting device in harsh environments, ensuring the engine can start at any time.

Ideal for remote mining sites, oil fields, or ships, they improve the reliability of diesel engine starts in specialized environments.

Conclusion: Ensure Stable Starting of Large Diesel Engines

The starting method for large diesel engines should be selected according to the application scenario, and effective maintenance measures should be taken to ensure that the engine can start efficiently at any time.

If your diesel engine requires a more stable starting solution, it is recommended to choose high-quality starting equipment and combine it with scientific maintenance methods to ensure the long-term reliable operation of the equipment.