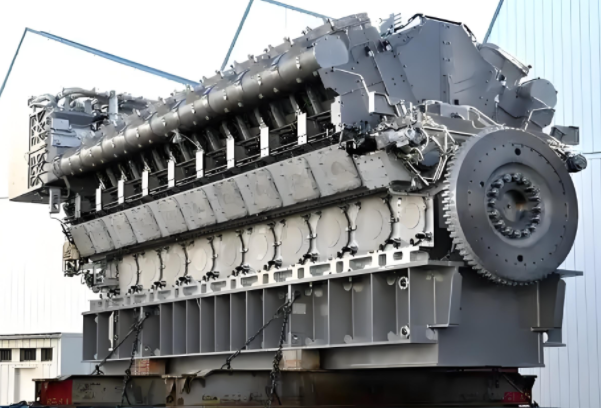

Marine diesel engines are the heart of a vessel’s power system and their smooth startup is directly related to safe navigation and efficient transportation. However, sometimes starting difficulties can be like the “heart disease” of the vessel, catching you off guard and delaying precious travel time.

So, how can these problems be solved? Here, we will take you through marine diesel engine starting problems, explore effective solutions, and help the vessel set sail smoothly.

Part 1. Common Marine Diesel Engine Starting Problems

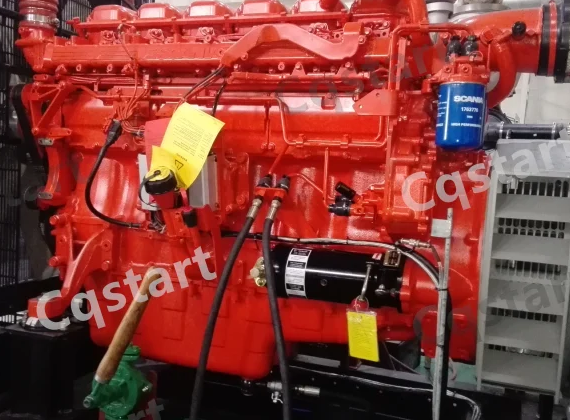

1. Fuel System Failures

Fuel system failures are one of the most common causes of marine diesel engine startup issues. If the fuel pipes, fuel pump, or fuel filter in the system are clogged or damaged, fuel cannot flow properly into the engine.

This issue is particularly noticeable during cold seasons when fuel can solidify or become contaminated with water, thus affecting engine startup.

2. Insufficient Battery Power

The battery is one of the key components for starting a diesel engine. If the battery is undercharged or aging, the engine will not be able to provide enough startup current.

Battery issues are especially evident in cold weather, as low temperatures accelerate battery power depletion, preventing it from meeting the engine’s starting demands.

3. Starter Motor Failures

The starter motor is responsible for turning the engine over to a startup position. If the starter motor malfunctions, such as through motor damage, circuit issues, or unstable power supply, the engine will fail to start. Starter motor failure is typically caused by prolonged wear or improper usage.

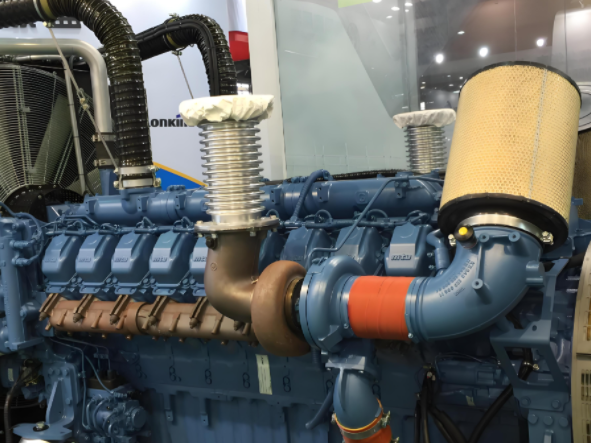

4. Cold Start Problems

Cold start problems occur when a diesel engine fails to start in low-temperature environments. The diesel engine in cold weather increases the viscosity of diesel fuel, requiring more power to start the engine, which places additional strain on the engine.

Older engines, in particular, are more susceptible to starting issues in cold temperatures.

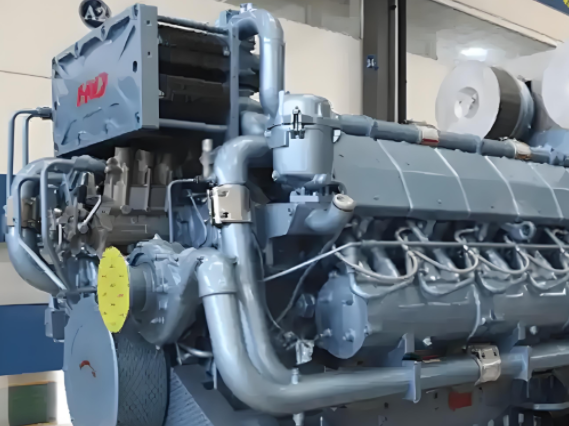

5. Compression System Failures

Insufficient cylinder pressure or worn piston rings in the compression system are also significant contributors to startup problems. If the compressed air in the cylinder cannot be properly sealed, it makes starting the engine difficult, or even impossible.

Part 2. How to Solve Marine Diesel Engine Startup Problems

1. Clean and Inspect the Fuel System

To prevent fuel system issues, it is essential to regularly check fuel pipes, fuel pump, and fuel filters. Ensure that fuel pipes are not clogged, and replace fuel filters as needed.

If the vessel operates in cold environments for extended periods, it’s advisable to use anti-gel additives to prevent fuel from waxing. A water separator can also be used to remove moisture from the fuel, preventing contamination.

2. Inspect and Replace the Battery

Battery power depletion is a common cause of startup problems. Regularly check the battery power and ensure that the terminals are free from corrosion. If the battery is old or cannot be charged, consider replacing it.

In cold environments, selecting a battery with strong cold-weather performance is critical. If the battery’s power is insufficient, a backup battery can be used for emergency engine startup.

3. Use a Spring Starter

A spring starter is a mechanical starting device that can provide starting power when the battery cannot supply enough current. Especially in cold environments, a spring starter uses mechanical energy from a spring to start the engine quickly.

Unlike battery-powered starting systems, spring starters do not rely on electricity, making them particularly suitable for situations where the battery is faulty or has insufficient charge. When marine diesel engines experience startup difficulties, a spring starter is an effective backup solution.

4. Inspect the Starter Motor

Starter motor failure typically leads directly to engine startup failure. To avoid starter motor issues, regularly inspect the motor to ensure the circuit is connected properly and the motor operates smoothly.

If a fault is detected, replace the starter motor in a timely manner. Using high-quality starter motors can also help reduce the frequency of failures.

5. Prevent Cold Start Issues

For cold start problems in low-temperature environments, several methods can be used to prevent or resolve the issue:

- Use Low-Temperature Starting Oil: This type of oil maintains a low viscosity in cold environments, aiding in smoother engine startups.

- Maintain the Cooling System: Ensure the engine’s cooling system is functioning properly to avoid overheating or freezing that may occur due to system failures.

- Use an Engine Preheater: In cold weather, using a preheater to warm up the engine before starting can help the diesel engine start smoothly, especially for engines that haven’t been used for a while.

6. Maintain Proper Compression System Functioning

Compression system failures are often caused by poor cylinder sealing, worn piston rings, or damaged valves. To keep the compression system functioning properly, regularly check cylinder pressure and promptly replace worn components when needed.

Maintaining a well-functioning compression system helps improve engine startup reliability and efficiency.

Part 3. How to Prevent Marine Diesel Engine Starting Problems?

1. Regular Maintenance

To effectively prevent marine diesel engine startup problems, regular and comprehensive maintenance is crucial. Regularly inspect key components such as the fuel system, battery, starting system, and cooling system to identify and resolve potential issues in a timely manner.

2. Use High-Quality Fuel

Using high-quality diesel fuel can significantly reduce fuel contamination and waxing issues. Additionally, regularly cleaning and replacing the fuel filter and keeping the fuel system running smoothly can help prevent startup problems caused by the fuel system.

3. Proper Use of Starting Equipment

Spring starters and starter motors are two critical devices that ensure smooth engine startup. Keeping these devices in good condition, with regular checks and maintenance, can effectively reduce the chances of startup failures.

4. Monitor the Engine Compression System

Regularly inspect the engine’s compression system, particularly the cylinder pressure and the condition of the piston rings. Identifying issues early and performing necessary repairs can effectively prevent startup problems caused by insufficient compression.

Part 4. Emergency Solutions for Marine Diesel Engine

1. Backup Battery Startup

When the battery power is insufficient, a backup battery can be used to emergency-start the engine. Ensure that the backup battery is fully charged and ready for use at any time.

2. Spring Starter Emergency Startup

If the battery cannot provide enough current, a spring starter can be used for an emergency engine startup. The spring starter does not rely on a battery, making it a very effective backup starting method.

3. Contact Professional Technicians

If the above measures do not resolve the startup problem, it is advisable to contact professional technicians for inspection and repair.

Especially when the issue involves key components such as the engine’s internal compression system or starter motor, professional maintenance is key to ensuring the engine’s long-term reliable operation.

Final Thoughts

Marine diesel engine starting problems are common issues in vessel operations, but most of these problems can be effectively addressed through regular maintenance, proper use of starting equipment, and timely emergency measures.

We hope that the information provided in this article will help you better resolve marine diesel engine startup issues and ensuring that your vessel remains in optimal operating condition.