Marine starter is a crucial part of the ship’s engine starting system. Whether for small fishing boats or large commercial vessels, a dependable starting system is essential for safe navigation and normal operation. In this post, we will provide a comprehensive overview of everything related to marine starters. Let’s take a look together!

Part 1. What is Marine Starter?

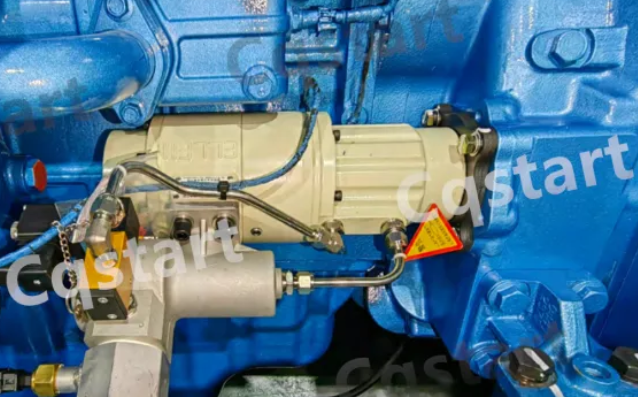

Marine starter is a starting device specifically designed for ships, used to start the main engine of the vessel. Unlike automotive starters, marine starters must be able to withstand the unique conditions found in marine environments, such as high humidity, salinity, and temperature fluctuations.

Marine starter is widely used on various types of vessels, including recreational yachts, fishing boats, large commercial ships, and industrial vessels.

Part 2. Types of Marine Starter

There are a variety of marine starters available on the market, designed to be compatible with different types of vessels and engine configurations. Here are some common types of marine starters:

Electric Starter

Electric starter is a crucial component for marine engines. The ship’s battery powers it, converting electrical energy into mechanical energy to start the engine. It generates torque by connecting with the flywheel and igniting the engine quickly.

Air Starter

Air Starter is a device that uses compressed air to start marine engines. It is commonly found on large ships and diesel engines. It starts by releasing compressed air stored in a gas tank to power the engine’s crankshaft. Air starter is renowned for their high reliability and robust starting capabilities.

It’s particularly suitable for systems that require high torque starting and can operate reliably in extreme environments.

Hydraulic Starter

Hydraulic starter is a device that starts a marine engine through hydraulic pressure. It is commonly used on heavy ships and large diesel engines. It uses a hydraulic pump to pressurize hydraulic oil into the starter, providing enough power to start the engine crankshaft when activated.

Hydraulic starter has high reliability and excellent starting ability. It is suitable for harsh environments and can ensure that the engine starts quickly and reliably. It is frequently used as a primary or backup system to enhance the safety and reliability of the overall starting system.

Spring Starter

Spring starter is a device that starts a marine engine by storing energy through a mechanical spring. The principle is that the spring is pre-compressed or coiled, and when released, the energy of the spring drives the crankshaft of the engine to start.

Spring starter is preferred because it is simple, reliable, and does not require power or compressed air. It’s particularly suitable for emergency situations or extreme environments. It is commonly used as a backup starting system in combination with other starters to ensure that the engine can start smoothly when needed.

Inertia Starter

Inertia starter is a device that uses the inertia of a flywheel to start a marine engine. It stores energy in a rapidly spinning flywheel and releases its kinetic energy to power the engine’s crankshaft when starting is required. Inertia starter is simple, durable, and efficient, making it suitable for use on large ships and heavy diesel engines.

Although less common in modern applications, this type of starter is still a reliable way to start, especially when electricity or other starting methods are unavailable.

Part 3. How Does a Marine Engine Starter Work?

The working principle of a marine engine starter is to convert electrical or other power sources into mechanical energy to start the main engine. When the engine starts, the starter receives a signal from the battery or other power source and begins operating.

An electric starter drives the flywheel or crankshaft through an electric motor, generating enough torque to start the engine, while air, hydraulic, or mechanical starters release stored energy using their respective power sources.

During the start-up process, the starter engages with the engine’s flywheel to guarantee that energy is released at the right moment, allowing the engine to start smoothly.

After the engine is started, the starter automatically disengages to prevent damage to the engine. The design of marine engine starters must take into account the marine environment’s special conditions, ensuring stable operation in high humidity and saline environments.

Part 4. How to Choose Right Marine Starter?

Choosing the right marine starter requires consideration of several factors, including ship size, engine type, and operating conditions. Here are some common guidelines for selecting:

Small Boats

For smaller boats, such as recreational or fishing boats, electric starters are usually the best choice. They start quickly, are easy to install, and the batteries usually provide a stable power supply.

Large Ships

For commercial vessels or vessels used for industrial purposes, air starters are popular due to their strong power and durability. These starters can perform well in scenarios that require high starting power.

Remote or Emergency Situations

When the vessel is sailing in remote waters or the power supply is unstable, spring starter is a reliable solution. Because it does not rely on external electricity or compressed air, the spring starter is the best choice for extreme conditions. In addition, it has the benefits of simple maintenance and long-term reliability.

Part 5. How to Start a Main Engine from a Dead Ship?

Starting a main engine from a dead ship can be a challenging situation, especially if there are no available power sources. However, using spring starter, like Cqstart spring starter, is an effective method to start dead ship, especially in a power outage.

Let’s see how to start main engine from dead ship with spring starter:

Step 1: Connect Spring Starter

Then, connect the spring starter to the engine’s starting mechanism and make sure all connections are tight and secure to prevent any disconnections during starting process. Also, spring starter should be properly aligned with the engine starter motor.

Step 2: Wind the Spring

Wind the spring starter according to the manufacturer’s instructions. Typically, you need to rotate a handle or lever until the spring is fully wound, storing enough energy to start the engine.

Then, you should ensure that the spring is fully wound and in a secure position to release energy.

Step 3: Starting the Engine

Once the spring starter is connected and ready, it’s time to start main engine from dead ship. You need to pull a lever or press a release button on starter to release the stored energy to start the engine. As the spring releases, the engine should start to turn over and rotate.

Wrap Up

Marine starter is crucial for starting a ship’s engine, as it affects safety and efficiency. Selecting the right starter: electric, air, or environmentally-friendly spring starters improves reliability and crew safety.

With technological advancements, spring starters are becoming a low-maintenance, electricity-free solution. Choosing the right starter ensures that your vessel is always ready for smooth sailing.