In the world of machinery and equipment, small diesel engines play a vital role, commonly used in agriculture, construction, and portable generators. Electric start systems have revolutionized engine technology, but they are not the only starting option.

In this post, you’ll explore everything about small diesel engine electric start, including its the working principle, pros and cons, ways to overcome these drawbacks, and other key insights. Let’s go!

Part 1. What is Small Diesel Engine?

Small diesel engines typically refer to those with a displacement of less than 10 liters, renowned for their high fuel efficiency, strong low-speed torque, and exceptional durability. These engines are ideal for heavy-duty and high-intensity work environments, making them an indispensable power source across various industries.

Common Applications of Small Diesel Engine:

Agricultural Equipment: Small diesel engines are widely used in agricultural machinery such as tractors, harvesters, and cultivators, providing powerful performance for soil cultivation and crop harvesting.

Construction Machinery: In the construction industry, these engines are commonly found in equipment like excavators, rollers, concrete mixers, and generators, ensuring smooth operations on site.

Marine Applications: Small boats and yachts often come equipped with diesel engines for efficient and reliable navigation.

Portable Power Sources: In outdoor activities and construction sites, portable diesel generators provide the power for equipment and tools.

Part 2. Working Principle of Small Diesel Engine Electric Start

The electric start system allows the diesel engine to be started by pressing a button or turning a key. Here are its main components and working principles:

Battery: The core of the electric start system, providing the necessary power.

Starter Motor: Converts the electrical energy from the battery into mechanical energy.

Flywheel: Connected to the starter motor, it rotates the engine’s crankshaft.

Ignition System: Delivers fuel and air to the combustion chamber, igniting the mixture to start the engine.

When the ignition switch is activated, the battery sends power to the starter motor. The motor, connected to the flywheel, rotates the engine to initiate start.

Part 3. Pros & Cons of Electric Start Small Diesel Engine

Pros of Small Diesel Engine with Electric Start

Convenience: Convenience is a major advantage of the electric start system, allowing operators to quickly and easily start the engine with just a simple push of a button.

Increased Efficiency: Electric start responds quickly, reducing starting time and improving work efficiency, enabling equipment to be used more quickly.

Suitable for Users: Whether for professional operators or casual users, the electric start system is user-friendly, lowering the barrier to operation and increasing user acceptance.

Cons of Small Diesel Engine with Electric Start

Dependency on Battery: Electric start system requires battery to provide power. If the battery is weak or damaged, the engine will not start, which can be particularly problematic in remote areas.

Maintenance Needs: The battery and electrical components require regular inspection and maintenance to ensure system reliability, which adds complexity and cost to maintenance.

Electrical Failure Risks: Issues with cables or connections can lead to starting failures, necessitating troubleshooting and repairs.

Sensitivity to Environmental Conditions: Extreme weather conditions (such as high or low temperatures) can affect the battery’s performance, affecting its starting effectiveness.

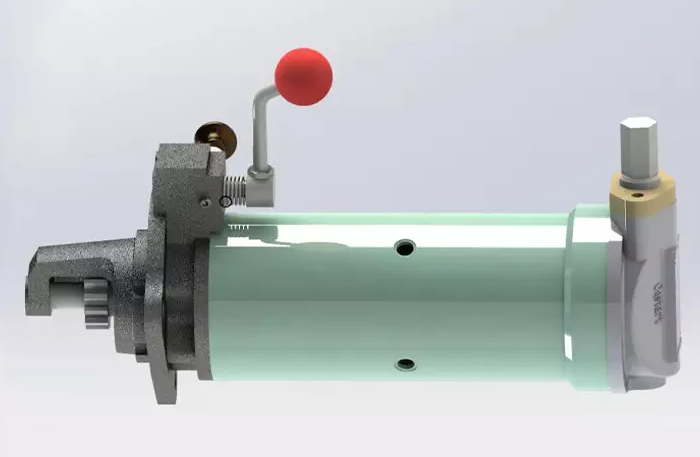

Part 4. Best Way to Conquer Electric Start Limitations – Spring Starter

While the electric start system offers great convenience, it also has some limitations, as previously mentioned. To address these problems, spring starter has become an effective solution.

Spring starter not only easily starts small engines but also effectively addresses the shortcomings of the electric start system. Next, let’s explore how spring starter overcome the disadvantages of electric starting and its advantages in practical applications.

No Power Source Needed: Spring starters don’t require a battery, allowing the engine to be started even in cases of insufficient or no power, making it ideal for remote areas or harsh environments.

Lower Maintenance Costs: Compared to electric start systems, spring starters require less maintenance, reducing repair costs and complexity associated with electrical failures.

High Durability: The robust design of the spring starter can withstand extreme weather conditions, ensuring reliable engine starts in various environments.

Quick Starting: Spring starters can quickly release energy, providing strong starting power and significantly reducing startup time.

Wide Applicability: Whether in agricultural equipment, construction machinery, or marine applications, spring starters can effectively replace traditional electric start systems or serve as a backup starting option, enhancing the overall reliability of the equipment.

Part 5. Key Considerations When Choosing Electric Start System

Battery Quality: A reliable battery is crucial for the efficient operation of electric start systems. When selecting an engine, consider the battery’s capacity and lifespan.

Maintenance Requirements: Understand the engine’s maintenance needs, including the care of the battery and electrical components, to develop a reasonable maintenance plan that ensures the long-term reliability of the system.

Environmental Factors: Consider the operating environment. For instance, in extremely cold climates, a high-quality battery may be necessary to ensure reliable start-ups.

Budget: When selecting an engine, you should also consider the initial cost, long-term maintenance, and fuel efficiency for an informed decision. This evaluation helps ensure performance while maximizing economic benefits.

Part 6. Wrap Up

Small diesel engine electric start represents a significant technological advancement, offering a convenient, reliable, and efficient starting method. When selecting a small diesel engine, it is important to consider all aspects of the electric start system. However, electric starting is not the only option for starting diesel engines. Spring starters can also serve as an excellent backup.

FAQs about Small Diesel Engine with Electric Start

1. Can a diesel engine run on electricity?

No, a diesel engine cannot run on electricity alone as it relies on diesel fuel for combustion. However, hybrid systems can combine diesel engines with electric motors to improve fuel efficiency and reduce emissions, using electricity to assist the diesel engine instead of replacing it.

2. What type of electric motor is commonly used to start small auxiliary diesel engines?

A starter motor, typically a DC electric motor, is commonly used to start small auxiliary diesel engines. It draws power from the battery to power the engine by turning the flywheel, initiating the combustion process. This type of motor is highly favored for its high torque at low speeds, which is crucial for starting diesel engines.

3. What is the minimum battery voltage to start a diesel engine?

The minimum battery voltage required to start a diesel engine is typically 12 to 14 volts. Most diesel engines use a 12-volt battery system, but some larger engines may require 24 volts. A low voltage can lead to slow cranking speeds or failure to start, as diesel engines typically require higher torque to start the combustion process compared to gasoline engines.