Small engine starter is a key component for starting small engines and is widely used in devices such as lawnmowers, motorcycles, marine engines, and portable generators. Choosing the right starter ensures efficient and reliable equipment startup. In this post, we will provide detailed information on small engine starters. Let’s take a look!

Part 1. What is Small Engine Starter and Its Types?

Small engine starter is a device that provides initial power to a small engine by driving the crankshaft to initiate ignition and bring the engine into normal operation.

Based on different starting methods, small engine starters come in various types that are suitable for different scenarios and requirements. Here are some common types of small engine starters.

Electric Starter

Electric starter uses battery power to drive a starter motor that starts the engine. Its starting process is quick and effortless, making it widely used in motorcycles, small generators, and other equipment where fast startup is essential.

Electric starter is very user-friendly; users only need to press the start button or turn a key to start the engine.

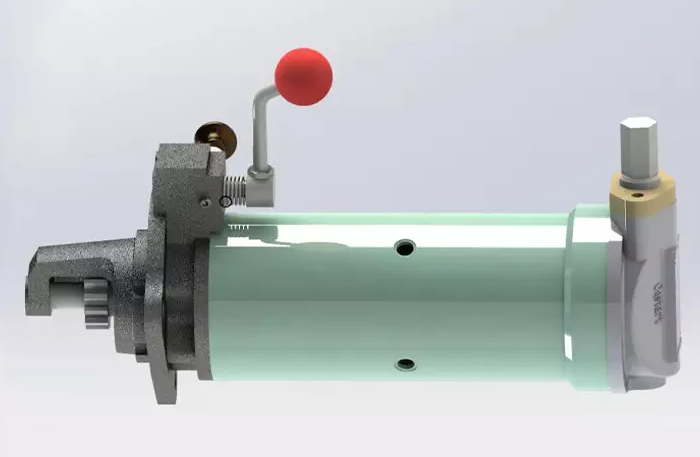

Spring Starter

Spring starter uses stored spring energy to start the engine, offering a power-free starting solution. The user compresses the spring by rotating the starter, and when released, the spring rapidly releases energy to drive the engine.

This type of starter is ideal for equipment used in remote or offshore locations, such as certain marine and diesel engines, and is known for its stable and reliable performance.

Pull Starter

Pull starter works by pulling a rope that drives the internal gear system of the starter, which in turn starts the engine. With its simple structure and low cost, pull starter is commonly used in small lawn mowers, chainsaws, and other similar equipment.

Although it requires some physical effort to operate, pull starter requires minimal maintenance and is suitable for use in areas without an external power supply.

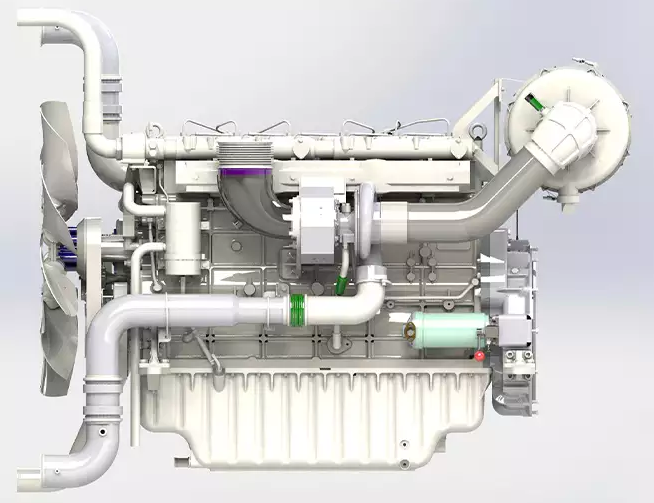

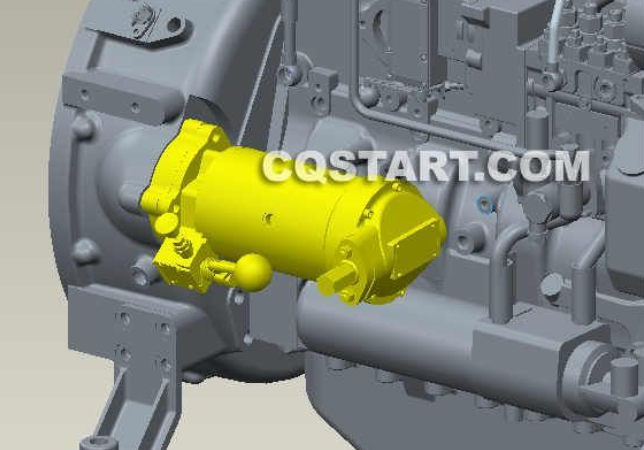

Air Starter

Air starter typically uses compressed air to start the engine and is often used with specific diesel and marine engines. This starter type provides quick startup, is suitable for various environments, and is commonly found in industrial and specialized applications due to its need for compressed air equipment.

Part 2. How Does Small Engine Starter Work?

The working principle of a small engine starter is to provide initial power to drive the engine’s crankshaft, initiating the ignition cycle and allowing the engine to enter normal operation. The process for each type of starter varies.

Electric Starter: Electric starter uses battery power to spin the starter motor, which turns the engine’s flywheel, moves the pistons, and ignites the engine. Once the engine starts, the starter motor automatically disengages from the engine.

Spring Starter: Spring starter compresses a spring by rotation, and when the spring is released, the stored energy powers the crankshaft to start the engine.

Pull Starter: Pull starter works by pulling a rope to drive an internal gear system, which then turns the crankshaft, initiating the combustion cycle and starting the engine.

Air Starter: Air starter uses compressed air to directly drive the crankshaft, starting the engine. It is commonly used in diesel engines and industrial equipment.

Part 3. Key Features of Small Engine Starter

The key characteristics of small engine starters include start-up efficiency, reliability, applicability, maintenance requirements, and ease of operation. These factors affect performance and the appropriate use scenarios for different types of starters. Here is a detailed look:

Start-Up Efficiency

The efficiency of a small engine starter directly affects the start-up speed and stability of the engine. Electric starters are highly efficient, allowing for quick ignition and smooth operation, making them ideal for equipment that requires fast starts.

Pull starters and spring starters, while slower, provide reliable options for remote areas without power sources.

Reliability

Reliability is a crucial factor, especially for small devices used outdoors or in specialized environments. Spring starters and air starters, which do not require power, are often better suited for harsh conditions.

Air starters, for instance, use compressed air instead of electricity to maintain stable performance across a range of temperatures and humidity levels, whereas electric starters may experience reduced efficiency in cold environments due to battery limitations.

Applicability

Different types of small engine starters are suitable for specific equipment needs. Electric starters are widely used in motorcycles and small generators, while pull starters, with their simple structure and low cost, are ideal for small tools such as lawnmowers and chainsaws.

Spring starters and air starters are often found in remote or power-free areas, such as marine engines and industrial equipment.

Maintenance Requirements

The maintenance needs for small engine starters vary based on the type. Electric starters require regular battery power and motor checks to ensure they can start the engine when needed.

Pull starters and spring starters, with their simpler construction, require minimal maintenance making them suitable for remote or maintenance-free locations. However, air starters require periodic checks of the compressed air system to ensure consistent performance.

Ease of Operation

The ease of operation directly affects the user experience. Electric starters are simple to operate and typically require only a button press or a key turn, making them ideal for equipment that requires frequent starting.

Pull starters require physical effort, while spring starters operate by rotating the starter to compress the spring, which requires less strength. On the other hand, air starters involve operating a compressed air system, which is better suited for use by industrial equipment operators.

Part 4. Factors to Consider When Choosing a Small Engine Starter

Different types and powers of small engines may require different types of starters. When selecting a starter, the power, type (such as gasoline or diesel), and start-up requirements should be considered to determine the appropriate type of engine.

Power Supply Considerations

Electric starters require battery power, so when selecting, the power supply situation of the equipment should be taken into account.

If the equipment is frequently used in areas without power, such as remote areas, a pull starter or spring starter may be a better choice as they do not rely on electricity. On the other hand, if a stable power supply is available, an electric starter is undoubtedly more convenient.

Ease of Operation

Ease of operation is an important factor for users when choosing a starter. Electric starters only require a press of a button or turning a key to start, making them ideal for equipment that requires frequent starts.

For some users, especially those with less physical strength, a pull starter may be less convenient as it requires some effort to operate. A spring starter is relatively easy to use, but it may require some skill and experience. Choosing the appropriate starting method based on usage scenario and user needs can greatly enhance the user experience.

Environmental Adaptability

The starter’s ability to adapt to its environment is also a crucial factor to consider. Some equipment may need to operate in harsh environments or extreme weather.

Electric starters may experience battery power shortages in cold environments, whereas spring starters and air starters are more reliable in cold or humid conditions. For equipment that needs to operate in harsh environments, choosing a starter with strong adaptability is crucial.

Maintenance and Durability

The maintenance needs and durability of a starter are also crucial factors to consider. Electric starters require regular monitoring of battery power and motor condition to prevent a failed start due to battery aging or motor damage.

Conversely, pull starters and spring starters have lower maintenance requirements, making them more suitable for environments where frequent maintenance is difficult. Choosing a durable starter with lower maintenance needs can reduce daily operating costs and reduce the likelihood of failures.

Cost-Effectiveness

The cost of different starter options is significantly different. Electric starters are usually more expensive but offer easier operation and higher starting efficiency.

Pull starters and spring starters are relatively low-cost, suitable for equipment with a limited budget or those with less demanding start-up needs. Considering the frequency of equipment usage and maintenance costs, choosing a cost-effective starter can save money in the long term.

Safety

The safety of small engine starters is also a factor that cannot be overlooked. With electric starters, their battery systems must meet safety standards to prevent issues such as short circuits or battery leakage.

Spring starters and air starters must ensure the safety of their spring or compressed air systems to prevent a sudden release of energy that could cause harm to the operator.

Part 5. How to Start a Small Engine?

Different starters have different starting procedures. Here we list some general procedures for starting a small engine with different types of starters.

Different starters have different starting procedures. Here we list some general procedures for starting a small engine with different types of starters.

1. Starting with an Electric Starter

An electric starter is a device powered by a battery to start the engine. It is easy to operate and starts quickly. The steps are as follows:

- Step 1. Ensure the battery is fully charged: Before starting, check if the battery has enough power. If the battery is low, charge or replace it.

- Step 2. Check fuel and coolant levels: Ensure that there is enough fuel in the tank, and coolant (if applicable) is at the proper level.

- Step 3. Ensure the device is in a safe position: If the device has a clutch or gear selector, ensure they are in “neutral” or “park” mode.

- Step 4. Check the surroundings: Make sure there are no obstructions around the equipment to avoid accidents.

- Step 5. Press the start button or turn the key: Most electric starters only require pressing a button or turning a key to start the engine. If there are any indicators or displays, check for error messages.

- Step 6. Wait for the engine to start: Electric starters typically start the engine quickly. If it doesn’t start, wait a few seconds and try again.

2. Starting with a Spring Starter

A spring starter uses stored energy from a spring to start the engine. This type of starter is used for certain diesel engines or marine engines. The steps are as follows:

- Step 1. Rotate the starter: Rotate the starter’s handle counterclockwise until you feel resistance, indicating the spring is compressed.

- Step 2. Release the spring: Quickly release the starter handle to allow the spring to release its stored energy, thus starting the engine.

- Step 3. Ensure safety: During this process, make sure the rotation direction of the starter matches the engine’s start-up direction, or it may damage the starter or engine.

3. Starting with a Pull Starter

Pull starters are commonly used for small devices such as lawnmowers and chainsaws. They work by pulling a cord to drive the internal gears and start the engine. The steps are as follows:

- Step 1. Check fuel and oil levels: Ensure that the fuel tank has enough fuel, especially if it’s a two-stroke engine that requires mixed oil.

- Step 2. Check the spark plug: Make sure the spark plug is not damaged or covered with carbon deposits and can ignite the mixture properly.

- Step 3. Prepare the pull cord: Hold the pull cord handle with one hand and ensure the device is stable with the other hand.

- Step 4. Pull the cord to start: Pull the cord firmly. If everything is in order, the engine will start.

- Step 5. Pull multiple times if necessary: Sometimes, it may take several pulls to start. Avoid pulling too hard to prevent damage to the cord or components.

4. Starting with an Air Starter

Air starters use compressed air to start the engine. This type of starter is usually used for large equipment or specialized applications. The steps are as follows:

- Step 1. Check the compressed air system: Ensure that the air pressure is sufficient and there are no leaks in the system. Typically, air starters require a certain amount of air reserve to operate correctly.

- Step 2. Connect the air hose: Attach the air hose to the starter’s air intake.

- Step 3. Start the device: Press the air starter button or switch to begin the engine. Compressed air will enter the starter and drive the engine to start.

- Step 4 .Check for any anomalies: Ensure that no issues, such as overloads or start-up failures, appear during the process.

Part 6. Future Trends of Small Engine Starter

As technology advances, small engine starters are improving. Electric starters will work with new energy sources for better efficiency and battery life. Smart starters will provide diagnostic features for easier maintenance.

Also, air and spring starters, with low energy use and zero emissions, will become more common in eco-friendly areas. These changes will make starters more efficient, smart, and environmentally friendly.

FAQs about Small Engine Starter

What is the difference between a mini starter and a regular starter?

A mini starter is smaller, lighter, and designed for small engines like motorcycles or lawnmowers, while a regular starter is larger, more powerful, and built for bigger engines like those in cars or trucks.

How many amps does a starter need to start?

The amps a starter needs depend on the engine size. Small engines require 50-150 amps, car engines need 100-200 amps, and larger diesel or industrial engines may need over 300 amps.

Why are small engine hard to start?

Small engines can be hard to start for several reasons, including fuel issues (such as old or contaminated fuel), a dead or weak battery, spark plug problems, or a clogged air filter. Furthermore, cold weather can cause the oil in the engine to become thicker, making it harder for the engine to spin up. Poor maintenance or improper storage can also lead to starting difficulties.

How does a starter work on a diesel engine?

A diesel engine starter uses an electric motor to turn the engine’s flywheel, which rotates the crankshaft and starts the combustion process. The battery powers the flywheel, and once the engine starts, the starter disengages automatically.