Are you tired of the hassle of starting diesel engines in extreme conditions? Well, here’s the solution! What is it? It’s the spring starter! In this article, we will introduce everything about spring starter, including the best spring starter for diesel engines, helping you easily start your diesel engine even in the harshest conditions.

Part 1. What is a Spring Starter?

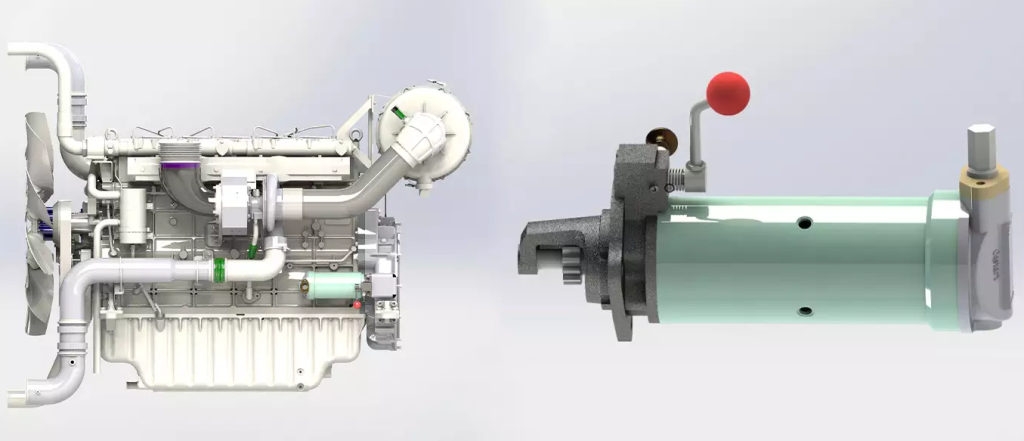

What is a spring starter? A spring starter is an innovative mechanical device primarily designed to assist in starting diesel engines. Unlike traditional electric starters that rely on batteries and electrical systems, the spring starter uses a coiled spring mechanism to generate the necessary force to start the engine.

The machine only requires manual cranking to convert manual energy into stored potential energy in the disc spring to start the engine. This makes it particularly useful in extreme or emergency situations.

Part 2. How Does a Spring Starter Work?

The spring starter work principle primarily converts stored potential energy into rotational kinetic energy. By manually winding and cranking the spring, the potential energy within the disc spring is transformed. When the potential energy is released all at once, it starts the engine.

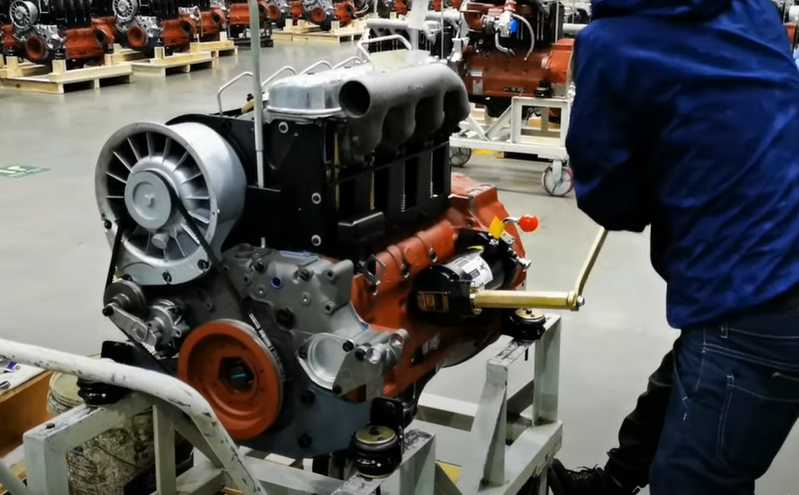

The operation for the spring starter is also very easy. First, manually wind the spring inside the starter, which stores potential energy as tension. Once the starter engages, the stored energy is released, rotating the engine’s crankshaft. This action initiates the engine’s combustion process, making it easier for the engine to start.

Part 3. Best Spring Starter for Diesel Engine – Cqstart Spring Starter

Cqstart is an experienced manufacturer specializing in the development and production of spring starters. Their products are suitable for various diesel engine models and specifications, covering engines from 2L to 50L in displacement.

They are the rare manufacturers in the market that can support large-displacement diesel engines and Cqstart spring starter holds the world record for compatibility with 50L displacement diesel engines.

Key Features of Cqstart Spring Starter

- Great Compatibility: It can be adapted to diesel engines ranging from low displacement to up to 50L.

- Excellent Quality: All Cqstart spring starters undergo rigorous testing, with detailed test data provided for each unit, ensuring quality assurance.

- High Reliability: Cqstart spring starters are purely mechanical devices that can withstand extreme temperatures and ensure smooth startup of diesel engines in harsh conditions.

- Low Maintenance Costs: Cqstart spring starters use high-quality maintenance-free grease, which effectively reduces friction and wear. Its maintenance-free design lowers maintenance costs.

- Safety: Cqstart spring starter features a pre-engagement design that is naturally explosion-proof, making it suitable for hazardous environments. All spring starters have a mini anti-lock mechanism to effectively prevent accidental engine starting.

Cqstart spring starters are an efficient, reliable, and environmentally friendly solution for starting diesel engines. They are widely used in various industrial and emergency equipment. If you are looking for a high-quality and dependable spring starter, Cqstart is your best choice.

Part 4. Key Consideration When Choosing Spring Starter

When choosing a spring starter, it’s important to not make a hasty decision. Selecting the right spring starter is crucial. In the selection process, it’s important to consider multiple factors to make an informed choice. Here are some key factors to consider when choosing a spring starter.

1. Engine Compatibility

First, you need to choose a spring starter that matches the diesel engine. Different engines have different sizes, types, and starting requirements, so selecting the right starter is crucial.

Each spring starter is designed to meet the needs of specific engine capacities. Using an incompatible starter can cause starting difficulties or damage to the equipment.

2. Environmental Conditions

The operating conditions for diesel engines can vary significantly, such as high or low temperatures. In such cases, it’s important to choose a spring starter that can reliably operate in harsh environments. If the diesel engine is primarily used in marine or humid environments, selecting a starter made from corrosion-resistant materials will be more advantageous.

3. Durability

When selecting a spring starter, it’s best to choose models made of durable and high-quality materials, as they can withstand frequent use over time. It’s also advisable to check the product’s expected lifespan or the number of cycles it can operate before replacing it. Opting for models with a longer lifespan ensures more durable performance and reliability.

4. Ease of Use

When selecting a spring starter, ease of operation is a key factor, especially in emergency situations where quick equipment startup is crucial. Choosing a starter that is easy to operate not only reduces the likelihood of errors but also enhances work efficiency.

Additionally, it’s important to choose a starter with a simple installation process to minimize installation time and unnecessary training costs, allowing the equipment to be put into service quickly and avoiding delays in normal workflows.

5. Maintenance Requirement

When choosing a spring starter, it’s crucial to choose models that require minimal maintenance. Compared to electric starters, mechanical starters require less upkeep, which not only reduces equipment downtime but also significantly reduces overall operational costs.

Additionally, starting workers with lower maintenance needs help avoid frequent work interruptions, ensuring continuity and efficiency in workflows, and boosting overall productivity.

6. Safety Features

When selecting a spring starter, it is crucial to ensure that it has a controllable spring energy release safety mechanism that is safe to use. This design effectively prevents accidental startup, ensuring that the engine does not start unexpectedly when not required, thus avoiding potential safety hazards.

If the spring starter is used in hazardous environments, consideration should be given to its explosion-resistant features. The explosion-resistant design provides additional safety in high-risk environments, reducing the likelihood of explosions or other incidents, and ensuring the safety of personnel and equipment.

Part 5. Benefits of Spring Starter for Diesel Engine

Using a spring starter greatly enhances the convenience and support for diesel engine startup. The spring starter simplifies the starting process mechanically, reducing reliance on electricity.

Spring starters offer high reliability and durability in environments with unstable or lacking power supplies, ensuring stable operation under various working conditions.

Enhanced Reliability: Spring starters are renowned for their robustness and dependability, especially in harsh weather conditions where traditional starters might fail. They are less affected by issues related to battery power and electrical systems.

Improved Efficiency: Spring starters eliminate the need for batteries, reducing the load on the vehicle’s electrical system. This efficiency results in a lighter load on the engine and improves overall performance.

Lower Maintenance Costs: With fewer electrical components, spring starters typically require less maintenance. Their simple design results in fewer failures, leading to reduced repair and replacement costs.

Part 6. Typical Applications of Spring Starter

1. Marine

Spring starters are commonly used in marine engines on ships, boats, and offshore platforms. They are particularly effective in marine environments where seawater corrosion can shorten battery life or cause electrical system failures. Furthermore, spring starters are also applied to emergency equipment such as lifeboats and onboard emergency generators. Their high reliability ensures that critical systems can start smoothly even without electrical power.

2. Industry

In construction, reliable solutions are needed to start heavy equipment like excavators, bulldozers, and cranes, especially in remote areas where maintaining electrical systems is challenging. Spring starters are an ideal choice in such scenarios.

Similarly, in mining operations, spring starters are commonly used to start heavy machinery such as transport trucks and drilling rigs’ diesel engines. These engines need to start reliably and consistently in harsh environments, including dust and extreme temperatures.

3. Emergency

Spring starters are an ideal choice for emergency generators used in hospitals, data centers, and critical infrastructure. They can start the generator quickly and reliably during power outages, even if the electrical starting system fails. Furthermore, spring starters are suitable for various emergency rescue scenarios, ensuring that critical equipment can function smoothly in emergency situations.

4. Military

In military areas, spring starters are widely used for various field equipment, such as tanks, military trucks, and other vehicles. They serve as a reliable starting point in areas where power is unstable or unavailable. Additionally, for portable generators used in field operations or remote bases, spring starters are a reliable alternative to battery-powered systems.

In Summary

Spring starters offer a practical and efficient solution for diesel engines, proving invaluable in a range of applications. In this post, we highlighted the highly acclaimed Cqstart spring starters, known for their exceptional performance and reliable quality, making them a trusted choice for engine starting needs.